Concrete Saw PME-Q350

When you are looking for a concrete saw, we can assist you in selecting the most suitable напольная пила for your business.

Concrete Saw PME-Q350

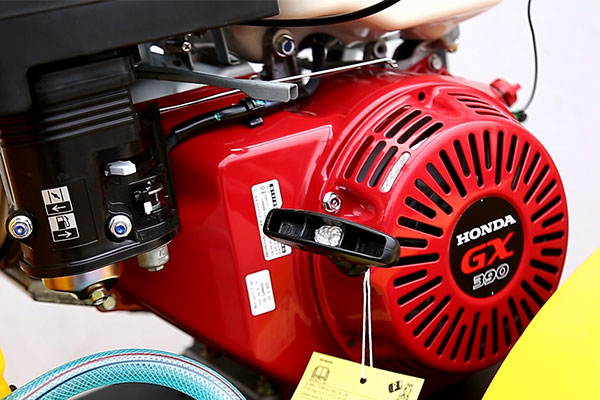

The PME-Q350 Concrete Saw is built for heavy-duty cutting performance, delivering precision and power for professionals tackling concrete, asphalt, and stone projects. With a robust max cutting depth of 11 cm and compatibility with 300 mm or 350 mm blades, this saw excels in deep slab scoring, demolition, and infrastructure repairs. Engineered for adaptability, it supports multiple engine configurations (Honda, Robin, Loncin, or diesel), ensuring optimal power for diverse job site demands.

Power & Precision

Equipped with a high-performance air-cooled, single-cylinder, 4-stroke petrol or diesel engine, the PME-Q350 guarantees reliable operation in tough conditions. Its handle-rotated depth adjustment allows quick, accurate depth customization, while the manual push-forward mode ensures controlled, steady cuts. The 10 L integrated water tank minimizes dust and prolongs blade life, enabling cleaner, safer cuts in concrete and reinforced materials.

Rugged Durability

Constructed with a heavy-duty steel frame and reinforced components, the PME-Q350 withstands rigorous use on construction sites. Weighing 70 kg (N.W.) and packaged compactly (83 x 55 x 95 cm), it balances portability with stability. Designed for versatility, it handles everything from shallow grooves to deep structural cuts, making it ideal for urban projects, roadwork, or industrial applications.

Versatile Applications

– Concrete slab demolition

– Road and pavement repair

– Trenching for utility lines

– Expansion joint creation

– Reinforced concrete cutting

– Masonry and stonework modification

– Bridge and infrastructure maintenance

– Precision cutting in tight spaces

Adaptable & Reliable

The PME-Q350 Concrete Saw adapts to your needs with its multi-engine compatibility, offering flexibility for fuel preferences or regional requirements. Whether powered by a trusted Honda petrol engine or a rugged diesel option, this tool delivers consistent performance for contractors, demolition crews, and municipal teams. Built to conquer challenging environments, it ensures efficiency and accuracy in every cut—from residential renovations to large-scale industrial projects.

Key Specifications

| Model | Concrete Saw PME-Q350 |

|---|---|

| Engine | Honda/Robin/Loncin/Diesel engine |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine/diesel engine |

| Max.cutting depth [cm] | 11 |

| Depth adjustment | Handle rotation |

| Forward mode | Manual push |

| Water tank capacity [L] | 10 |

| Blade size [mm] | 300;350 |

| N.W./G.W [kg] | 70/75 |

| Package (L x W x H) [cm] | 83x55x95 |

ADVANTAGE

Lifter Shaft

Easy Crank For Raising Or Lowering Cutting Depth.

Power Engine

Strong And Stable. Electric,Gasoline, Diesel Power Can Be Customized Upon Request

Water Tank

The Large-Capacity Water Tank Ensures Sufficient Water Supply And Good Cooling Effect.

Thickened Guide Wheel

Accurately Locate The Depth Of Cut And Keep Walking In A Straight Line

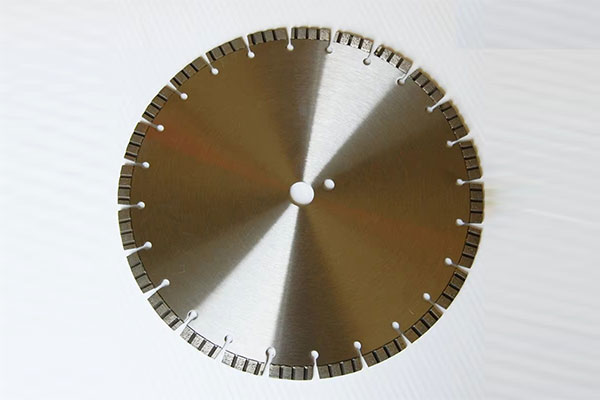

Saw Blades

Saw Blades With Uniform Thickness And Sharp Cutting, With Diameters Of 300mm-800mm.

Blade Cover

Intensive Thicken Blade Cover ,Walking Never Shaking And Level Wheel Keep Cutting In Line

QUESTIONS & ANSWERS

The lifespan of a concrete saw blade can vary based on usage and maintenance. Generally, a well-maintained blade can last anywhere from 20 to 100 hours of cutting time.

Yes, concrete saws can be used for various materials, including brick, stone, and even some metals, depending on the blade type used.

Signs that a blade needs replacement include visible wear, cracks, or chips, as well as decreased cutting efficiency. If the blade is not cutting smoothly, it may be time for a replacement.

While concrete saws can be operated by beginners, it is essential to receive proper training and guidance. Understanding safety protocols and best practices is crucial for safe operation.

When using a concrete saw, consider dust control measures and noise reduction strategies to minimize environmental impact. Using water to cool the blade can also help reduce dust and improve cutting efficiency.

Other Similar Products

Продается пластинчатый компактор PME-C100

Vibrating Plate Compactor PME-C95T

Vibratory Plate Compactor PME-C90

Plate Tamper PME-C85T

Soil Compactor PME-C80T

Machine Compactor PME-C80

20+ лет опыта

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, трамбовка, дорожный каток,напольная пила, бетонный вибратор, генератор и т.д.

Concrete Saw

A concrete saw, often referred to as a concrete cutter, is a specialized power tool designed for cutting through concrete, asphalt, brick, and other hard materials. These saws are essential in various construction and renovation projects, providing the precision and efficiency needed to create clean cuts. Whether you are a professional contractor or a DIY enthusiast, understanding the capabilities and features of concrete saws can significantly enhance your project outcomes.

Types of Concrete Saws

Concrete saws come in several types, each tailored for specific applications. The most common types include:

-

Handheld Concrete Saws: These portable saws are ideal for smaller jobs or tight spaces. They are often used for cutting concrete slabs, curbs, and other small-scale applications.

-

Walk-Behind Concrete Saws: Designed for larger projects, these saws are equipped with powerful engines and can cut deeper and wider than handheld models. They are typically used for road construction and large-scale concrete cutting.

-

Wall Saws: These saws are specifically designed for cutting vertical surfaces, such as walls and foundations. They are often used in demolition and renovation projects.

-

Floor Saws: These are specialized saws used for cutting floors, particularly in industrial settings. They can handle heavy-duty tasks and are often equipped with larger blades.

Key Features of Concrete Saws

Blade Types and Sizes

The effectiveness of a concrete saw largely depends on its blade. Blades come in various sizes and types, including diamond blades, which are ideal for cutting through hard materials like concrete and asphalt. The size of the blade will determine the depth and width of the cut, so it’s essential to choose the right blade for the job. For instance, a larger blade can cut deeper, while a smaller blade may be more suitable for intricate work.

Power Sources

Concrete saws can be powered by different sources, including gas, electric, or hydraulic systems. Gas-powered saws are typically more portable and suitable for outdoor use, while electric saws are quieter and ideal for indoor applications. Hydraulic saws offer high power and efficiency, making them suitable for heavy-duty tasks. When selecting a power source, consider the specific requirements of your project and the environment in which you will be working.

Особенности безопасности

Safety is paramount when operating a concrete saw. Many modern concrete saws come equipped with safety features such as blade guards, emergency shut-off switches, and vibration dampening systems. These features help protect the operator and ensure safe operation. Additionally, some saws have dust control systems to minimize airborne particles, which is crucial for maintaining a safe work environment.

Applications of Concrete Saws

Construction Projects

In construction, concrete saws are used for a variety of tasks, including cutting expansion joints, creating openings for doors and windows, and removing damaged concrete. Their precision allows for clean cuts, which are essential for the integrity of the structure.

Renovation and Repair

Concrete saws are invaluable in renovation and repair work. They are used to cut out sections of damaged concrete for replacement, ensuring that repairs are done efficiently and effectively. This can include cutting concrete slabs, walls, or even driveways.

Utility Installation

When installing utilities such as water, gas, or electrical lines, concrete saws are often employed to cut through pavement or concrete. This allows for easy access to underground infrastructure without causing extensive damage to the surrounding area.

How to Choose the Right Concrete Saw

Assessing Your Cutting Needs

Before purchasing a concrete saw, it’s essential to assess your specific cutting needs. Consider the types of materials you will be cutting, the frequency of use, and the size of the projects you typically undertake. For instance, if you frequently work on large projects, a walk-behind saw may be more suitable than a handheld model.

Comparing Brands and Models

Not all concrete saws are created equal. Research different brands and models to find one that fits your requirements. Look for reviews and testimonials from other users to gauge performance and reliability. Some reputable brands are known for their durability and efficiency, which can save you money in the long run.

Бюджетные соображения

Concrete saws can vary significantly in price. Set a budget before shopping and consider the long-term value of the saw. Investing in a high-quality concrete saw may save you money on repairs and replacements in the future. Additionally, consider the cost of replacement blades and maintenance when budgeting for your purchase.

Operating a Concrete Saw Safely

Средства индивидуальной защиты (СИЗ)

Safety should always be the top priority when operating a concrete saw. Operators should wear appropriate personal protective equipment (PPE), including safety goggles, gloves, ear protection, and sturdy footwear. A dust mask or respirator may also be necessary to protect against airborne particles.

Предоперационные проверки

Before using a concrete saw, conduct a thorough pre-operation check. Inspect the blade for damage, ensure all safety features are functioning, and check fluid levels if applicable. This helps prevent accidents and equipment failure. Additionally, familiarize yourself with the saw’s controls and operation manual.

Лучшие практики во время эксплуатации

When operating a concrete saw, follow best practices to ensure safety and efficiency. Maintain a steady pace, avoid forcing the saw, and always be aware of your surroundings. If you’re new to using a concrete saw, consider seeking guidance from an experienced operator. Proper training can significantly reduce the risk of accidents.

Maintenance Tips for Concrete Saws

Regular Cleaning and Inspection

To keep your concrete saw in optimal condition, regular cleaning and inspection are crucial. Remove debris and dust after each use, and inspect the blade and other components for wear and damage. A clean saw operates more efficiently and lasts longer.

Blade Maintenance

The blade is one of the most critical components of a concrete saw. Regularly check for dullness or chips, and replace the blade as needed. Proper blade maintenance can significantly extend the life of your saw. Additionally, ensure that the blade is properly aligned and tightened before use.

Поиск и устранение неисправностей

Common issues with concrete saws include overheating, difficulty starting, and uneven cuts. Familiarize yourself with troubleshooting techniques to address these problems quickly and efficiently. If you encounter persistent issues, consult the manufacturer’s manual or seek professional assistance.

Заключение

Concrete saws are indispensable tools in the construction and maintenance industries. Their ability to cut through tough materials with precision makes them essential for a variety of applications, from road construction to utility installation. By understanding the features, applications, and maintenance of concrete saws, operators can ensure they are using these powerful tools safely and effectively.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Premier Construction Machinery Manufacturer with OEM Capabilities

We stand as a preeminent player in the construction machinery sector, presenting high - end Original Equipment Manufacturer (OEM) services. Our dedication to innovation, coupled with meticulous precision in engineering, guarantees that the machinery we produce caters precisely to the unique requirements of our clients. We deliver tailor - made solutions that significantly boost efficiency and optimize performance at every construction site.

20 Years of Production and Export Experience

Having amassed two decades of hands - on experience in both production and export activities, we've forged a solid reputation for supplying dependable and top - tier construction equipment across the globe. Our in - depth understanding and proficiency within the industry empower us to recognize the distinct obstacles presented by various markets. This awareness ensures that our products are customized to adhere to international standards.

There are more than 20 types of construction site equipment for you to choose from.

We present an extensive variety of upwards of 20 different kinds of construction site equipment, which can satisfy a wide array of industry demands. Spanning from heavy - duty machinery to specialized implements, our product portfolio is crafted to assist in every stage of the construction process. This enables our clients to have the freedom to pick the most suitable equipment for their respective projects.

Over 10 - year QC for Product Quality Monitoring

Our stringent quality control procedures have been honed over a period of more than a decade. This ensures that each item of equipment manufactured by us adheres to the most elevated standards. Our committed quality control team painstakingly oversees every phase of the production process. As a result, we can assure that our products exhibit unwavering performance and long - lasting durability when deployed in the field.

Skilled Workers with 8+ Years of Experience

Our workforce is made up of highly proficient workers who have accumulated more than 8 years of experience within the construction machinery sector. Their in - depth knowledge and unwavering commitment are evident in the meticulous precision and fine craftsmanship of our products. Every minute detail is carried out flawlessly, thanks to their expertise.

8 Workshops and 12 Production Lines

We possess 8 modern workshops and 12 production lines, which are configured to adeptly handle large - scale requirements. These advanced facilities enable us to execute a smooth and efficient production process. As a result, we can ensure that high - quality machinery is promptly delivered to our global clientele. Our well - equipped workshops and production lines serve as the backbone for meeting the extensive demands of the market with precision and speed.

Revolutionize Construction Efficiency with Our Engineered-to-Perform Machinery

Uncover a realm filled with state – of – the – art construction equipment meticulously crafted to satisfy the requirements of contemporary work sites. Boasting 20 years of immersion in the industry and an unwavering dedication to excellence, our machinery is ingeniously designed to enhance productivity and guarantee steadfast reliability across all projects. Dive into our extensive array and experience the distinctiveness of solutions engineered with precision.