Concrete Cutting Saw PME-Q400

When you are looking for a concrete cutting saw, we can assist you in selecting the most suitable scie à sol for your business.

Concrete Cutting Saw PME-Q400

The PME-Q400 Découpe du béton Saw is purpose-built for professionals demanding precision, performance, and durability in concrete and asphalt cutting tasks. Engineered to handle intensive construction and renovation projects, this saw accommodates blade sizes of 300 mm, 350 mm, and 400 mm, reaching a maximum cutting depth of 13 cm. Whether for deep scoring or utility trenching, the PME-Q400 offers a dependable solution for contractors, road crews, and demolition teams alike.

Power Meets Precision

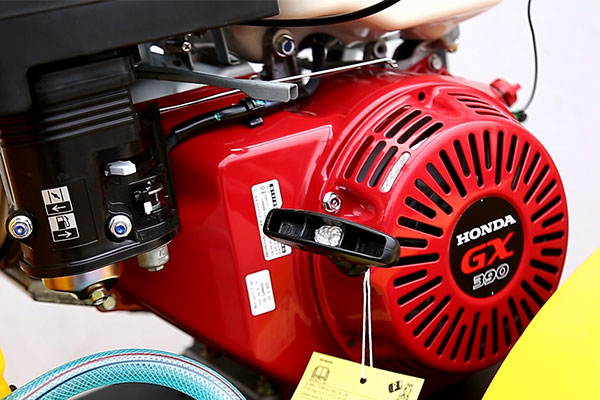

Equipped with options for Honda, Robin, Loncin, or diesel engines, the PME-Q400 features a reliable air-cooled, single-cylinder, 4-stroke engine—available in both petrol and diesel variants. Its handle-rotation depth adjustment mechanism allows users to set precise cutting depths on the fly, ensuring sharp, clean cuts even in demanding site conditions. The manual push-forward mode supports operator-controlled movement, providing maximum stability for intricate or deep cuts.

Built Tough for Jobsite Conditions

Crafted with a robust steel frame and reinforced components, the PME-Q400 is designed to endure the stress of heavy-duty cutting operations. It weighs 90 kg net (100 kg gross), striking the perfect balance between ruggedness and maneuverability. A generous 25-liter integrated water tank optimizes cooling and dust suppression, significantly improving blade life and cutting efficiency.

Despite its solid construction, the PME-Q400 remains compact and transport-friendly, with packaging dimensions of 99 x 55 x 87 cm. This makes it easy to store, load, and relocate across various job sites.

Wide Range of Uses

Deep concrete cutting

Utility trench preparation

Pavement and roadway repairs

Expansion joint installations

Asphalt and masonry cutting

Renovation and demolition work

Concrete floor and slab removal

Confined space applications

Professional-Grade Reliability

The PME-Q400 Concrete Cutting Saw is tailored for professionals who need a reliable, user-friendly machine capable of meeting the high demands of urban infrastructure, commercial renovations, and heavy-duty repair work. With its versatile blade compatibility, powerful engine options, and operator-friendly features, this saw is a must-have for crews requiring consistent performance and precise results in tough working environments.

Key Specifications

| Modèle | Concrete Cutting Saw PME-Q400 |

|---|---|

| Moteur | Honda/Robin/Loncin/Diesel engine |

| Type de moteur | Air-cooled,single cylinder,4-stroke,petrol engine/diesel engine |

| Max.cutting depth [cm] | 13 |

| Depth adjustment | Handle rotation |

| Forward mode | Manual push |

| Water tank capacity [L] | 25 |

| Blade size [mm] | 300;350;400 |

| N.W./G.W [kg] | 90/100 |

| Emballage (L x L x H) [cm] | 99x55x87 |

ADVANTAGE

Lifter Shaft

Easy Crank For Raising Or Lowering Cutting Depth.

Power Engine

Strong And Stable. Electric,Gasoline, Diesel Power Can Be Customized Upon Request

Water Tank

The Large-Capacity Water Tank Ensures Sufficient Water Supply And Good Cooling Effect.

Thickened Guide Wheel

Accurately Locate The Depth Of Cut And Keep Walking In A Straight Line

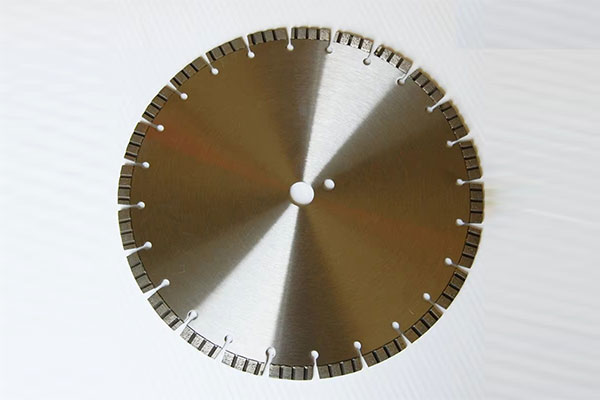

Saw Blades

Saw Blades With Uniform Thickness And Sharp Cutting, With Diameters Of 300mm-800mm.

Blade Cover

Intensive Thicken Blade Cover ,Walking Never Shaking And Level Wheel Keep Cutting In Line

QUESTIONS & ANSWERS

The lifespan of a road saw blade can vary based on usage and maintenance. Generally, a well-maintained blade can last anywhere from 20 to 100 hours of cutting time.

Yes, road saws can be used for various materials, including brick, stone, and even some metals, depending on the blade type used.

Signs that a blade needs replacement include visible wear, cracks, or chips, as well as decreased cutting efficiency. If the blade is not cutting smoothly, it may be time for a replacement.

While road saws can be operated by beginners, it is essential to receive proper training and guidance. Understanding safety protocols and best practices is crucial for safe operation.

When using a road saw, consider dust control measures and noise reduction strategies to minimize environmental impact. Using water to cool the blade can also help reduce dust and improve cutting efficiency.

Other Similar Products

Plate Compactor For Sale PME-C100

Vibrating Plate Compactor PME-C95T

Compacteur vibrant à plaque PME-C90

Autoprotection de plaque PME-C85T

Compacteur de sol PME-C80T

Machine Compacteur PME-C80

Plus de 20 ans d'expérience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, pilon de bourrage, rouleau compresseur,scie à sol, vibrateur de béton, générateur, etc.

concrete cutting saw

A concrete cutting saw, également connu sous le nom de concrete saw, cut-off saw, or road saw, is a powerful tool designed to cut through solid materials like concrete, asphalt, masonry, brick, and stone. These machines are essential for construction, renovation, and demolition projects, allowing workers to make precise and efficient cuts in tough surfaces.

Introduction to Concrete Cutting Saws

Whether you’re a construction professional, a demolition expert, or a DIY enthusiast, concrete cutting saws are essential tools that can make or break a project. These powerful machines are specifically designed to slice through the toughest materials—reinforced concrete, masonry, stone, and asphalt—with accuracy and efficiency.

As the construction industry grows, so does the demand for high-performance cutting tools. Concrete cutting saws have evolved to offer greater power, precision, and convenience than ever before. From handheld models to walk-behind units, the options are as varied as the jobs they tackle.

In this guide, we’ll dive deep into the best concrete cutting saws on the market, what to look for before buying one, and how to use them safely and effectively.

Why Concrete Cutting Saws Are Essential

Concrete is a staple in modern construction, but cutting it is no small feat. Without the right tool, you risk damaging the material, wasting time, or even causing injury. A concrete cutting saw ensures:

-

Precise cuts for structural integrity

-

Faster work completion

-

Minimized dust and debris when paired with proper attachments

-

Enhanced safety with built-in features like anti-vibration handles and blade guards

Whether you’re cutting expansion joints, demolishing slabs, or installing utilities, a quality concrete saw is indispensable.

Key Features to Look for in a Concrete Cutting Saw

Before dropping serious cash on a concrete cutting saw, it’s crucial to understand the features that affect performance, usability, and longevity.

Blade Types and Their Uses

| Blade Type | Meilleur pour | Notes |

|---|---|---|

| Diamond Blades | Reinforced concrete, masonry | Offers clean, precise cuts |

| Abrasive Blades | Asphalt, softer materials | Cheaper but wears quickly |

| Wet Cutting Blades | Concrete slabs | Reduces dust and cools the blade |

| Dry Cutting Blades | Small tasks or remote areas | Generates more dust, less ideal for heavy jobs |

Power Source Options

| Type | Pour | Cons |

|---|---|---|

| Gas-Powered | Most powerful, portable | Noisy, emissions, maintenance-heavy |

| Électrique | Cleaner, quieter | Needs power source, limited mobility |

| Battery-Powered | Cordless convenience | Limited runtime, less power |

Types of Concrete Cutting Saws

There are several types of concrete saws, each designed for specific applications:

-

Walk-Behind Saws (Floor Saws):

Ideal for cutting large concrete slabs or asphalt. These heavy-duty saws are commonly used for roadwork and large construction sites. They’re powered by gasoline, diesel, or electric engines. -

Handheld Saws:

Smaller and portable, these are suitable for detailed cutting or tight spaces. They can be electric, hydraulic, pneumatic, or gas-powered. -

Wall Saws:

Used for vertical cutting in walls or steep surfaces. These are track-mounted systems that allow for controlled, clean cuts. -

Wire Saws:

Equipped with a diamond-coated wire, these are used for cutting through very thick sections of concrete or reinforced structures. They’re common in bridge and dam demolition.

Blade Types

Concrete cutting saws use different blades depending on the material and depth of cut:

-

Diamond Blades: Most common for cutting concrete. These are embedded with synthetic diamonds for cutting through tough materials efficiently.

-

Abrasive Blades: Cheaper but wear out faster. Typically used for short-term or budget-conscious jobs.

Principales caractéristiques à prendre en compte

-

Power Source: Electric (cleaner, quieter), Gasoline/Diesel (more powerful, used outdoors), or Hydraulic/Pneumatic (used in special applications).

-

Blade Diameter: Determines the depth of cut; larger blades cut deeper.

-

Cutting Depth: Depending on the project, you’ll need the appropriate blade and saw combo.

-

Water Feed System: Helps to reduce dust and cool the blade during operation.

-

Safety Features: Blade guards, anti-vibration systems, and emergency shut-off controls are important for operator safety.

Applications

-

Cutting control joints in concrete slabs

-

Removing damaged sections of pavement or flooring

-

Creating openings for doors, windows, and HVAC systems

-

Demolishing concrete structures in construction projects

-

Trenching for utilities and plumbing

Safety Tips for Using Concrete Cutting Saws

Concrete saws are powerful—and potentially dangerous. Stay safe with these key practices:

Équipement de protection individuelle (EPI)

-

Safety glasses or face shield

-

Dust mask or respirator (especially dry cutting)

-

Protection auditive

-

Steel-toed boots

-

Heavy-duty gloves

Safe Handling Techniques

-

Always start the saw on a flat surface

-

Check blade tightness before each use

-

Never force the blade—let it do the work

-

Use water attachment when possible to reduce dust

-

Don’t cut above shoulder height

Work Area Safety

-

Clear the area of debris and flammable materials

-

Use caution tape if working in public zones

-

Maintain solid footing and balance at all times

Maintenance Best Practices

Taking proper care of your concrete cutting saw isn’t just about extending its lifespan—it’s about ensuring safe and efficient operation on every job. Here’s how to keep your saw running like new.

Daily Maintenance Checklist

Before and after each use, make these checks routine:

-

Inspect the blade: Look for cracks, warping, or dull edges. Replace worn blades immediately.

-

Clean the air filter: A clogged filter reduces engine efficiency. Use compressed air to clean it out.

-

Vérifier les niveaux de liquide: Fuel, oil, and (for wet saws) water tank levels should be checked daily.

-

Tighten nuts and bolts: Vibration during operation can loosen hardware.

Weekly & Monthly Maintenance

-

Change engine oil (gas models): Every 20-25 hours of use or as specified by the manufacturer.

-

Lubricate moving parts: Hinges, handles, and guard mechanisms need occasional oiling.

-

Inspect drive belts: Look for signs of wear or fraying and replace if necessary.

-

Test safety features: Blade guards, emergency shutoffs, and throttle control should function smoothly.

Conseils de stockage

-

Drain fuel before long-term storage to prevent gumming.

-

Store in a dry, clean area away from direct sunlight and extreme temperatures.

-

Cover the saw to protect it from dust and debris.

Common Mistakes to Avoid When Cutting Concrete

Even experienced operators can fall into bad habits. Avoid these pitfalls to protect your equipment, your health, and your project timeline.

Top Mistakes

-

Using the wrong blade for the job

Not all blades are created equal. A dry blade on a wet-cutting task, or an abrasive blade on reinforced concrete, can burn out quickly. -

Skipping blade calibration

Cutting depth and alignment must be checked before each use to ensure accuracy. -

Overheating the saw

Especially with dry cuts, failing to give your saw cooling breaks can lead to blade warping and engine damage. -

Not managing dust properly

Concrete dust is hazardous. Use wet cutting or dust extraction systems whenever possible. -

Poor posture and handling

Using a saw with incorrect body alignment can lead to injuries and uneven cuts.

Environmental Considerations and Dust Control

Concrete cutting produces a significant amount of silica dust—a known health hazard. Contractors are now expected to comply with environmental and occupational safety standards like those set by OSHA.

Effective Dust Control Methods

| Method | Description | Pour | Cons |

|---|---|---|---|

| Wet Cutting | Uses water to suppress dust | Very effective, cools blade | Requires water source, cleanup needed |

| Dust Extractors | HEPA vacuums attached to saw | Dry cutting made safer | Equipment cost |

| Enclosures/Barriers | Isolates cutting area | Protects others in vicinity | Not feasible for all job sites |

Sustainability Tips

-

Choose low-emission tools.

-

Recycle concrete debris when possible.

-

Reduce fuel usage by planning efficient cuts.

External Resource: For more on silica safety, check OSHA’s Silica Standard.

Where to Buy Concrete Cutting Saws

You can purchase concrete cutting saws from:

-

Authorized dealers

-

Online retailers like DIMEC

-

Secondhand platforms (e.g., Craigslist or Facebook Marketplace – inspect thoroughly before buying)

-

Tool rental stores for short-term jobs

Conseil de pro : Always verify warranty terms and service availability in your area.

Conclusion

A concrete cutting saw is more than just another tool in your arsenal—it’s the key to efficiency, precision, and professional results on any tough construction or demolition task.

Before purchasing, always consider your job scope, required cutting depth, power source preferences, and dust control needs. With proper maintenance and safe handling, your investment will serve you well for years to come.

Remember: Whether you’re working on a residential driveway or a commercial foundation, the right saw can make all the difference.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Premier Construction Machinery Manufacturer with OEM Capabilities

We stand as a preeminent player in the construction machinery sector, presenting high - end Original Equipment Manufacturer (OEM) services. Our dedication to innovation, coupled with meticulous precision in engineering, guarantees that the machinery we produce caters precisely to the unique requirements of our clients. We deliver tailor - made solutions that significantly boost efficiency and optimize performance at every construction site.

20 Years of Production and Export Experience

Having amassed two decades of hands - on experience in both production and export activities, we've forged a solid reputation for supplying dependable and top - tier construction equipment across the globe. Our in - depth understanding and proficiency within the industry empower us to recognize the distinct obstacles presented by various markets. This awareness ensures that our products are customized to adhere to international standards.

There are more than 20 types of construction site equipment for you to choose from.

We present an extensive variety of upwards of 20 different kinds of construction site equipment, which can satisfy a wide array of industry demands. Spanning from heavy - duty machinery to specialized implements, our product portfolio is crafted to assist in every stage of the construction process. This enables our clients to have the freedom to pick the most suitable equipment for their respective projects.

Over 10 - year QC for Product Quality Monitoring

Our stringent quality control procedures have been honed over a period of more than a decade. This ensures that each item of equipment manufactured by us adheres to the most elevated standards. Our committed quality control team painstakingly oversees every phase of the production process. As a result, we can assure that our products exhibit unwavering performance and long - lasting durability when deployed in the field.

Skilled Workers with 8+ Years of Experience

Our workforce is made up of highly proficient workers who have accumulated more than 8 years of experience within the construction machinery sector. Their in - depth knowledge and unwavering commitment are evident in the meticulous precision and fine craftsmanship of our products. Every minute detail is carried out flawlessly, thanks to their expertise.

8 Workshops and 12 Production Lines

We possess 8 modern workshops and 12 production lines, which are configured to adeptly handle large - scale requirements. These advanced facilities enable us to execute a smooth and efficient production process. As a result, we can ensure that high - quality machinery is promptly delivered to our global clientele. Our well - equipped workshops and production lines serve as the backbone for meeting the extensive demands of the market with precision and speed.

Revolutionize Construction Efficiency with Our Engineered-to-Perform Machinery

Uncover a realm filled with state – of – the – art construction equipment meticulously crafted to satisfy the requirements of contemporary work sites. Boasting 20 years of immersion in the industry and an unwavering dedication to excellence, our machinery is ingeniously designed to enhance productivity and guarantee steadfast reliability across all projects. Dive into our extensive array and experience the distinctiveness of solutions engineered with precision.