Bomba de agua diesel

Description

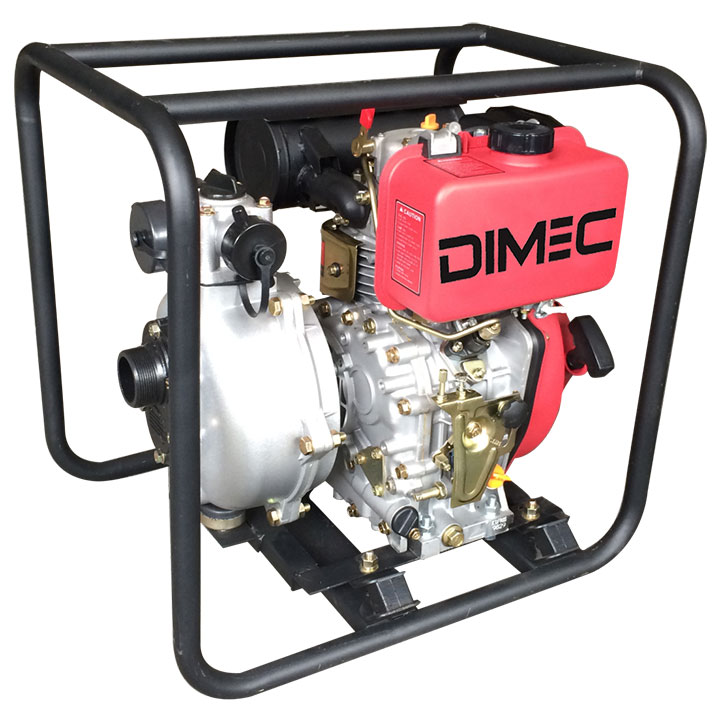

The air-cooled diesel water pump with compact structure, small size, easy installation and high efficiency, is self-priming single-stage centrifugal water pumps.The body of the water pump is constructed of high quality die-cast aluminum alloy. The internal rotating rings are constructed of ceramics and the stationary rings are constructed of grahite.It is ideal for general purpose use such as draining pools, ponds, and sumps of clear water. This clear water pump has a powerful diesel engine, making it ideal for remote water irrigation.

Aluminium Water Pump

Light weight

Lightweight aluminum pump which makes it easier to be transported anywhere.

Strong protection frame

The water pump has welded rugged steel roll cage. It gives the pump maximum protection at the jobsite and while transporting. The wide base gives rock-solid stability.

Silicone carbide mechanical seal

The high quality silicone carbide mechanical seals are harder, tougher and stronger than common aluminum oxide seals and have superior resistance to corrosion, wear and heat. To ensure the water pump no leakage and long working life.

| Model | PME50D(E) | PME80D(E) | PME100D(E) |

|---|---|---|---|

| Inch | 2'' | 3'' | 4' |

| Lifting height [m] | 25 | 28 | 25 |

| Suction head [m] | 7 | 7 | 7 |

| Rated capacity [m³/h] | 30 | 60 | 85 |

| Engine model | PME170F(E) | PME178F(E) | PME186FA(E) |

| Tipo de motor | Single-cylinder, vertical, air-cooled, 4-stroke, diesel engine | ||

| Sistema de arranque | Arranque por retroceso o arranque eléctrico | ||

| Capacidad del depósito de combustible [L] | 2.5 | 3.5 | 5.5 |

| Tiempo de funcionamiento continuo [h] | 2.5 | 2.5 | 2.5 |

| N.W/G.W [kg] | 35/38 | 44/50 | 75/80 |

| Paquete (L x A x A) [cm] | 51x43x54 | 58x46x57 | 67x49x63 |

Trash Pump

| Modelo | PME80T |

|---|---|

| Inch | 3'' |

| Lifting height [m] | 26 |

| Suction head [m] | 7 |

| Rated capacity [m³/h] | 78 |

| Engine model | PME178F(E) |

| Tipo de motor | Single-cylinder, vertical, air-cooled, 4-stroke, diesel engine |

| Sistema de arranque | Arranque por retroceso o arranque eléctrico |

| Capacidad del depósito de combustible [L] | 3.5 |

| Tiempo de funcionamiento continuo [h] | 2.5 |

| N.W/G.W [kg] | 68/73 |

| Paquete (L x A x A) [cm] | 60x47x57 |

Cast Iron Water Pump

It is ideal for general purpose use such as draining pools, ponds, and sumps of clear water. This clear water pump has a powerful diesel engine, making it ideal for remote water irrigation.

Durable and Efficient

To ensure the best performance, longer life and smoother operation, we gave this heavy-duty water pump a cast iron impeller and volute to increase pump life.

check valve

The cutting-edge check valves hold a prime when the pump is not running to quickly get you back up and pumping.

| Modelo | PME50C(E) | PME80C(E) | PME100C(E) |

|---|---|---|---|

| Inch | 2'' | 3'' | 4'' |

| Lifting height [m] | 75 | 75 | 50 |

| Suction head [m] | 7 | 7 | 7 |

| Rated capacity [m³/h] | 30 | 60 | 85 |

| Engine model | PME178F(E) | PME186FA(E) | PME192F(E) |

| Tipo de motor | Single-cylinder, vertical, air-cooled, 4-stroke, diesel engine | ||

| Sistema de arranque | Arranque por retroceso o arranque eléctrico | ||

| Capacidad del depósito de combustible [L] | 3.5 | 5.5 | 5.5 |

| Tiempo de funcionamiento continuo [h] | 2.5 | 2.5 | 2.5 |

| N.W/G.W [kg] | 50/55 | 79/85 | 81/86 |

| Paquete (L x A x A) [cm] | 52x46x58 | 58x49x63 | 58x49x63 |

High Pressure Water Pump

High lift, high flow

The cast iron water pump is high lift, high flow, which is suitable for irrigation in mountainous region, hills…

DURABLE and high power

Theacst iron material is strong and durable.

Diesel engine supply ample power for the

toughest conditions

| Model | PME40H(E) | PME50H(E) | PME80H(E) |

|---|---|---|---|

| Inch | 1.5'' | 2'' | 3'' |

| Lifting height [m] | 55 | 65 | 70 |

| Suction head [m] | 7 | 7 | 7 |

| Rated capacity [m³/h] | 20 | 30 | 38 |

| Engine model | PME178F(E) | PME178F(E) | PME186FA(E) |

| Tipo de motor | Single-cylinder, vertical, air-cooled, 4-stroke, diesel engine | ||

| Sistema de arranque | Arranque por retroceso o arranque eléctrico | ||

| Capacidad del depósito de combustible [L] | 3.5 | 3.5 | 5.5 |

| Tiempo de funcionamiento continuo [h] | 2.5 | 2.5 | 2.5 |

| N.W/G.W [kg] | 46/50 | 47/51 | 64/69 |

| Paquete (L x A x A) [cm] | 58x49x57 | 58x49x57 | 67x49x63 |

Mantenimiento

Engine periodic maintenance schedule

| Cada uso | 1er mes o 20 Hrs. | Cada 3 meses o 100 Hrs. | Cada 6 meses o 500 Hrs. | Cada año o 1000 Hrs. | |

|---|---|---|---|---|---|

| Comprobación y llenado de combustible | √ | ||||

| Descarga de combustible | √ | ||||

| Comprobación y llenado de aceite | √ | ||||

| Comprobar la fuga de aceite | √ | ||||

| Comprobar y apretar la tornillería exterior | √ | ||||

| Cambiar el aceite | √ | √ | |||

| Cambiar el filtro de aceite | √ | ||||

| Cambiar el elemento del filtro de aire | √(1) | ||||

| Filtro de combustible limpio | √(2)(cambio) | ||||

| Comprobar la bomba de aceite de alta presión | √(2) | ||||

| Comprobar boquilla | √(2) | ||||

| Comprobar el tubo de combustible | √(2) | ||||

| Ajustar las aberturas de entrada y salida de aire | √(2) | √(2) | |||

| Compuerta de entrada y salida de aire de rectificado | √(2) | ||||

| Cambio de segmentos | √(2) | ||||

| Comprobar la solución electrolítica del acumulador | Cada mes | ||||

| Comprobar el cepillo eléctrico y el anillo deslizante | √(2) | ||||

| Comprobar la resistencia del aislamiento | Dejar de trabajar es más de 10 días | ||||

Se realiza cada mes indicado o cada intervalo de horas de funcionamiento, lo que ocurra primero.

(1)Mantenimiento más frecuente cuando se utiliza en zonas polvorientas.

(2)Estos elementos deben ser reparados por su distribuidor a menos que usted disponga de las herramientas adecuadas y tenga conocimientos mecánicos. Consulte los procedimientos de mantenimiento en el manual.