Escarificadora

Description

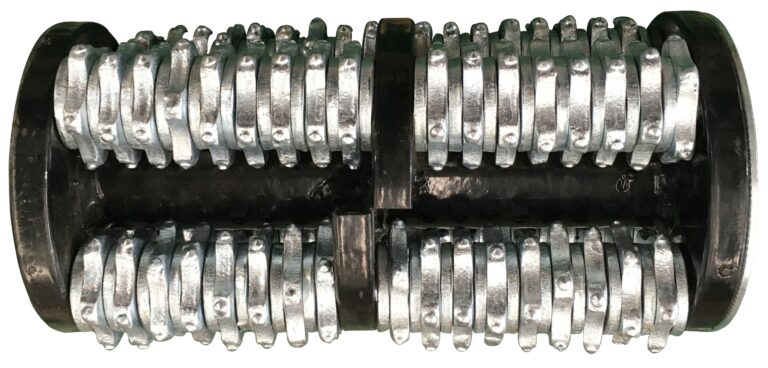

With scarifying, cutters are loosely fitted on lateral shafts which are then placed inside a drum housing. The drum is placed inside the machine and once the machine is switched on, the rotating drum generates centrifugal force which throws the cutter at the surface, causing a mechanical cutting action. Dust and contaminants are moved to a dedicated dust collector. This makes the process almost dust-free in operation.

Características

- Scarifying depth is adjustable

- Front mounting lifting handle for easy transportation

- Heavy duty shock buffer mounts to reduce vibration toward handle and engine

- Outlet dust-proof device

- Sealed bearing extend usage life

- Asphalt blades and cement blade as optional

| Modelo | PME-SM20H |

|---|---|

| Motor | Honda GX160 |

| Tipo de motor | Air-cooled,single cylinder,4-stroke,petrol engine |

| Displacement [cc] | 163 |

| Engine power [HP] | 5.5 |

| Rated power [KW] | 3.05 |

| Speed [RPM] | 3600 |

| Sistema de arranque | Manual start |

| Employed fuel | 93# |

| Employed oil | 10W-30 |

| Capacidad del depósito de combustible [L] | 3.6 |

| Oil tank capacity [L] | 0.65 |

| Working width [cm] | 20 |

| Scarifying depth [mm] | 1.6-3.0 |

| Milling spindle QTY | 4 |

| Efficiency [m2/h] | 70 |

| N.W./G.W. [kg] | 64/69 |

| Paquete (LxAnxAl) [cm] | 104x44x97 |

| Modelo | PME-SM25H |

|---|---|

| Motor | Honda GX390 |

| Tipo de motor | Air-cooled,single cylinder,4-stroke,petrol engine |

| Displacement [cc] | 389 |

| Engine power [HP] | 13 |

| Rated power [KW] | 6.6 |

| Speed [RPM] | 3600 |

| Sistema de arranque | Manual start |

| Employed fuel | 93# |

| Employed oil | 10W-30 |

| Capacidad del depósito de combustible [L] | 6.5 |

| Oil tank capacity [L] | 1.1 |

| Working width [cm] | 25 |

| Scarifying depth [mm] | 2-5 |

| Milling spindle QTY | 4 |

| Efficiency [m2/h] | 100 |

| N.W./G.W. [kg] | 115/125 |

| Paquete (LxAnxAl) [cm] | 97x58x109 |

Mantenimiento

Scarifying machine periodic maintenance schedule

| Time/Contents | Daily Before Starting | After First 5 Hrs. | After First 50 Hrs. | Every Week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

|---|---|---|---|---|---|---|

| Check fule level | √ | |||||

| Check oil level of machine | √ | |||||

| Check fule line and fittings for cracks or leaks | √ | |||||

| Check and tighten engine cylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Check V-belt | √ | |||||

| Clean engine cooling fins | √ | |||||

| Check and clean spark plug gap | √ | |||||

| Check and clean spark plug | √ | |||||

| Clean recoil starter | √ | |||||

| Clean engine muffler and exhaust port | √ |

Note: If engine performance is poor,please check,clean and replace air filter elements as needed.

Engine periodic maintenance schedule

| Cada uso | First month or 20 hours | Every 3 months or 50 hours | Every 6 months or 100 hours | Every year or 300 hours | ||

|---|---|---|---|---|---|---|

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Limpiar | √(1) | |||||

| Replace | √☆ | |||||

| Sediment Cup | √ | |||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Spark arrester(optional parts) | Limpiar | √ | ||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel tank and strainer | Limpiar | √(2) | ||||

| Combustion chamber | Limpiar | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

☆ Replace the paper element type only.

(1)Mantenimiento más frecuente cuando se utiliza en zonas polvorientas.

(2)Estos elementos deben ser reparados por su distribuidor a menos que usted disponga de las herramientas adecuadas y tenga conocimientos mecánicos. Consulte los procedimientos de mantenimiento en el manual.

Se realiza cada mes indicado o cada intervalo de horas de funcionamiento, lo que ocurra primero.