Tamper Rammer PME-RM85

When you are looking for a tamper rammer, we can assist you in selecting the most suitable tamping rammer for your business.

The PME-RM85 Tamper Rammer is a high-performance machine designed for heavy-duty soil compaction tasks. With a robust 345 x 285 mm plate and a powerful tamping force of 15 KN, it achieves a leap height of 80 mm, making it ideal for compacting dense and cohesive soils across various construction projects.

Powerful Performance

Powered by a choice of Honda, Robin, Loncin, or diesel engines, the PME-RM85 provides exceptional reliability and versatility. Its air-cooled, single-cylinder, 4-stroke engine is paired with a 3 L fuel tank, ensuring extended operation times and consistent power output. Operating at a frequency of 680 VPM, this tamper rammer delivers robust and reliable compaction, making it suitable for demanding applications on construction sites.

Versatile Application

The PME-RM85 is engineered for precision and power, excelling in confined spaces and challenging conditions. Its strong tamping force and moderate leap height make it perfect for compacting cohesive soils such as clay and silt, as well as mixed soil types. Whether you are preparing foundations, compacting trenches, or stabilizing subgrades, this tamper rammer ensures exceptional results for professional contractors and rental services.

Built to Last

Built with durability in mind, the PME-RM85 features high-quality materials designed to endure continuous use in tough working environments. Its sturdy construction ensures reliable performance for projects such as subgrade preparation, pipeline bedding, and landscaping. This rammer is built to deliver consistent results while standing up to the rigors of daily use.

Applications

- Trench and Pipeline Compaction

- Foundation and Footing Preparation

- Subgrade and Base Layer Compaction

- Retaining Wall Bases

- Road and Asphalt Repair Work

- Cohesive and Mixed Soil Compaction (e.g., clay, silt)

- Soil Stabilization for Construction and Landscaping

- Confined or Narrow Space Compaction

With its exceptional tamping force, versatile engine options, and durable construction, the PME-RM85 Tamper Rammer is a reliable solution for all soil compaction needs. It’s an indispensable tool for construction professionals and rental providers, offering unmatched performance and efficiency.

Key Specifications

| Model | Tamper Rammer PME-RM85 |

|---|---|

| Engine | Honda / Robin / Loncin / Diesel engine |

| Engine type | Air-cooled, single cylinder, 4-stroke, petrol engine / diesel engine |

| Fuel tank [L] | 3 |

| Leap height [mm] | 80 |

| Frequency [VPM] | 680 |

| Tamping force [KN] | 15 |

| Plate size (LxW) [cm] | 345x285 |

| N.W./G.W. [kg] | 83/93 |

| Package (LxWxH) [cm] | 79x44x115 |

ADVANTAGE

Reinforced Fuel Tank

The fuel tank is built from impact-resistant materials with secure fittings, ensuring reliable fuel storage and preventing leakage under demanding work conditions.

Robust Engine

Equipped with a powerful, reliable engine from renowned brands, ensuring smooth performance with low noise, minimal maintenance, and fuel efficiency.

Advanced Shock Absorption System

Enhanced shock-absorbing design significantly reduces vibration to the operator’s hands, providing a comfortable and controlled operation experience.

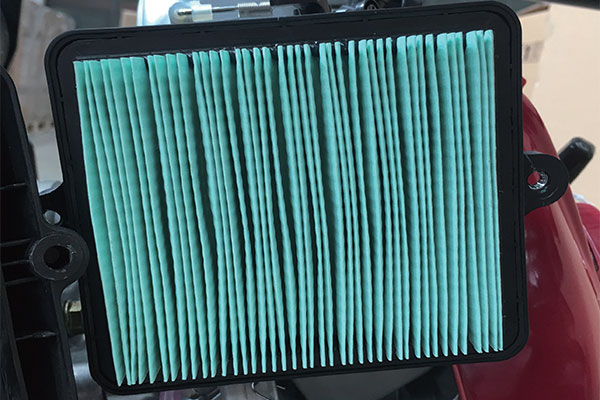

Efficient Air Purification System

A sophisticated air filter system effectively traps dust and debris, keeping the engine cleaner and reducing maintenance needs for extended performance life.

Polyurethane Folding Bellow

High-strength, flexible polyurethane bellow offers improved durability and longevity, resisting cracking and deformation even under heavy-duty use.

Durable Baseplate

A reinforced baseplate built from high-quality steel, designed for maximum stability and optimal compaction efficiency on various terrains.

QUESTIONS & ANSWERS

A tamper rammer is used to compact soil, gravel, and other materials, creating a solid base for construction projects.

Tamper rammers use rapid, repetitive force generated by their engine and a piston mechanism to compact soil deeply and evenly.

While tamper rammers excel on cohesive soils, they may require specific configurations for loose or granular materials.

While both are used for compaction, tamper rammers are ideal for small, confined spaces and tougher soils, whereas plate compactors work better on larger, flat areas.

Durability, performance, operator comfort, and advanced safety features distinguish quality models from mediocre ones.

With proper care, a high-quality tamper rammer can last upwards of 10 years, making it a worthwhile investment.

Regular maintenance is key. Check the engine, replace filters, and inspect parts after every 50-100 hours of operation or as specified by the manufacturer.

Yes, many modern models feature fuel-efficient engines and low emissions, making them more environmentally friendly.

Always wear protective gear, ensure proper footing, and follow the manufacturer’s guidelines to prevent accidents.

Other Similar Products

Concrete Cutting Saw PME-Q400

Concrete Saw PME-Q350

Road Saw PME-Q300

Ride On Vibro Roller PME-R6000

Road Roller Compactor PME-R3500

Construction Road Roller PME-R3000

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Tamping Rammer

Tamping rammers play a vital role in modern construction, widely used for their efficiency in compacting soil, gravel, and other granular materials. Known for their high-impact motion, tamping rammers stabilize soil, providing strong foundations for roads, pathways, and buildings. providing the compacted surfaces necessary for various building applications. Their powerful impact force and versatility make them a top choice for contractors and builders alike, ensuring strong and reliable foundations in every project.

What Are the Key Features of a Good Tamper Rammer?

Introduction to Tamper Rammers

What is a Tamper Rammer?

A tamper rammer, sometimes referred to as a jumping jack, is a high-impact compaction tool specifically engineered to create solid and stable surfaces. It is a must-have for construction workers and landscapers aiming to lay the groundwork for buildings, roads, and pavements. Unlike other compaction equipment like vibratory plates, tamper rammers exert a focused force that penetrates deeper, making them perfect for cohesive soils like clay or silt.

Importance of Choosing the Right Tamper Rammer

The significance of a quality tamper rammer lies in its ability to save time and effort while delivering exceptional results. Poor equipment can lead to uneven surfaces, structural instability, and even safety hazards. With the right machine, users can ensure precision, reliability, and an overall smoother workflow.

Design and Build Quality

Robust Frame Construction

The frame serves as the skeleton of the tamper rammer, and its durability determines the machine’s lifespan. Premium models use materials like industrial-grade steel or aluminum to resist the wear and tear of daily use. The frame should be corrosion-resistant to withstand challenging environments, including construction sites exposed to water or chemicals.

Ergonomic Design for Operator Comfort

Prolonged use of a tamper rammer can cause operator fatigue, especially if ergonomics are neglected. Modern designs incorporate vibration-dampening technology, padded grips, and balanced weight distribution. These features not only enhance comfort but also prevent long-term physical strain, such as hand-arm vibration syndrome (HAVS).

Power and Performance Features

Engine Specifications and Efficiency

A tamper rammer’s engine must be powerful enough to deliver consistent performance. High-end models often feature 4-stroke engines, which are quieter and more fuel-efficient than their 2-stroke counterparts. The choice of fuel type—gasoline, diesel, or electric—also impacts performance and usability, with electric models gaining popularity for their eco-friendliness.

Impact Force and Compaction Depth

The impact force, typically measured in kilonewtons (kN), indicates the tamper’s ability to compact the soil. Machines with adjustable impact force settings allow users to tailor performance to specific soil conditions. The compaction depth, often ranging from 20 to 30 cm, ensures a stable foundation for heavy-duty applications.

Fuel Efficiency and Runtime

Longer runtimes reduce downtime, enabling operators to complete tasks more efficiently. Fuel-efficient engines not only save money but also minimize environmental impact, a growing concern in the construction industry.

Ease of Operation

User-Friendly Controls

Intuitive controls simplify the learning curve for new operators. Features like throttle levers, start-stop buttons, and accessible fuel indicators make the machine easier to operate, even for novices.

Maneuverability in Confined Spaces

Compact tamper rammers are ideal for projects requiring precision in narrow or awkward spaces, such as trenching or pipe installations. A lightweight yet sturdy build further enhances maneuverability.

Durability and Maintenance

Wear-Resistant Materials

High-wear components like the foot pad, often made of high-carbon steel or polyurethane, are engineered to endure repetitive impacts. This longevity reduces the frequency of replacements, ensuring consistent performance.

Simplified Maintenance and Serviceability

Good tamper rammers feature accessible service points for tasks like oil changes, air filter replacements, and spark plug inspections. Many manufacturers include detailed user manuals and even onboard diagnostic systems to guide maintenance.

Safety Features

Anti-Vibration Systems

Excessive vibration can lead to operator fatigue and injuries. Advanced anti-vibration systems, such as shock-absorbing mounts and padded grips, reduce these risks significantly, allowing for longer operational hours.

Safety Shutdown Mechanisms

Automatic shutdown features, triggered by overheating or low oil levels, protect both the machine and the operator from potential hazards.

Key Features of a Good Tamper Rammer

Durability and Build Quality

One of the first things to look for in a tamper rammer is its durability. Machines built with high-quality materials like reinforced steel frames and wear-resistant components are designed to withstand harsh job site conditions. A durable tamper rammer won’t just survive the elements; it will also handle constant vibration and impact without breaking down.

Engine Performance

The engine is the heart of any tamper rammer. A good machine features an engine with adequate power output to deliver consistent performance, even on challenging terrains. Additionally, fuel-efficient engines can save you money and reduce environmental impact. Brands offering modern engines with low emissions are an added bonus.

Ease of Operation

Who wants to wrestle with a machine that feels like it has a mind of its own? User-friendly controls, ergonomic handles, and excellent maneuverability make a tamper rammer easier to operate. Look for models with intuitive control panels and designs that minimize physical effort for the operator.

Compaction Efficiency

The primary purpose of a tamper rammer is compaction, so its efficiency in this area is critical. Factors like the plate size, impact force, and the ability to work effectively on uneven surfaces determine how well it performs. High compaction power means fewer passes are needed, saving time and energy.

Shock Absorption System

Continuous vibration during operation can lead to operator fatigue and even injuries. A good tamper rammer includes a shock absorption system that minimizes vibrations transmitted to the user. This not only protects the operator but also extends the lifespan of the machine by reducing wear and tear.

Portability

Portability might not seem like a big deal until you’re faced with moving a heavy machine across a worksite. Lightweight and compact designs make tamper rammers easier to transport and store. Some models even come with built-in wheels or handles for added convenience.

Additional Features That Enhance Performance

Adjustable Handle Height

An adjustable handle allows operators of different heights to use the machine comfortably, making it more ergonomic.

Low Vibration Technology

Advanced models incorporate low vibration technology to ensure a smoother and more comfortable experience for the operator.

Noise Reduction Systems

Construction sites are noisy enough. Machines with noise-dampening features are a blessing for both workers and the surrounding environment.

Safety Features

Safety features like emergency shut-off switches and protective covers are must-haves. They minimize risks and make operation safer for everyone involved.

Benefits of Investing in a Quality Tamper Rammer

A good tamper rammer isn’t just a tool—it’s an investment. Durable and efficient models last longer, perform better, and require less maintenance. They can significantly improve project timelines, reduce costs, and deliver superior results.

How to Choose the Best Tamper Rammer

Assessing Your Project Needs

Different projects require different levels of compaction. Understand your requirements before making a purchase.

Budget Considerations

While quality is key, it’s also important to find a machine that fits your budget. Compare features and prices to get the best value.

Brand Reputation and Reviews

Stick to brands known for reliability. Customer reviews and expert recommendations can provide insights into a machine’s real-world performance.

Use Cases and Applications

Construction and Roadwork

Tamper rammers are indispensable for compacting sub-base layers in road construction. Their deep compaction ensures a stable foundation capable of supporting heavy traffic loads.

Landscaping and Foundation Work

In landscaping, these machines help create leveled surfaces for pathways, patios, and retaining walls. They are also crucial for preparing the foundation of structures, ensuring long-term stability.

Economic Value and Cost Efficiency

Initial Investment vs. Long-Term Value

While the upfront cost of a high-quality tamper rammer might seem steep, its durability and performance pay off in the long run. Cheap alternatives often require frequent repairs or replacements, making them more expensive over time.

Resale Value of Quality Tamper Rammers

Well-maintained equipment retains its value, offering a high resale price when it’s time to upgrade.

Environmental Considerations

Emissions Compliance

Many modern tamper rammers meet stringent emissions standards, such as EPA or EU Stage V certifications. These eco-friendly machines reduce pollutants, aligning with global sustainability goals.

Noise Levels and Neighborhood Impact

For projects in residential areas, low-noise models minimize disturbances, ensuring compliance with local noise ordinances and maintaining good relations with neighbors.

Conclusion and Key Takeaways

A good tamper rammer combines durability, efficiency, safety, and operator comfort to deliver exceptional performance across a variety of applications. Whether you’re preparing a foundation for construction or compacting soil for landscaping, investing in a quality model ensures long-lasting results and peace of mind.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.