Jumping Jack Tamper PME-RM70

When you are looking for a jumping jack tamper, we can assist you in selecting the most suitable tamping rammer for your business.

Jumping Jack Tamper PME-RM70

The PME-RM70 Jumping Jack Tamper is engineered for high-impact soil compaction, ideal for contractors and professionals handling demanding compaction tasks. With a solid 345 x 285 mm plate and delivering an impressive tamping force of 14 KN, this tamper achieves a leap height of 85 mm, making it highly effective for compacting dense and cohesive soils.

Powerful Performance

Powered by a choice of Honda GXR120, Robin EH12-2D, or Loncin LC165F-3H engines, the PME-RM70 ensures dependable and powerful performance. The air-cooled, single-cylinder, 4-stroke petrol engine, paired with a 2.8 L fuel tank, supports long operational hours on challenging projects. Operating at a frequency of 690 VPM, this jumping jack tamper provides consistent, robust impact to compact soils efficiently, making it suitable for heavy-duty projects on construction sites.

Versatile Application

The PME-RM70 is designed for versatility, excelling in tight spaces where precision and power are essential. It’s an ideal solution for cohesive soils such as clay and silt, as well as mixed types, ensuring thorough compaction in applications like trenching, foundation preparation, and pipeline work. This tamper is a valuable asset for contractors, rental services, and professionals needing high-impact equipment for specialized tasks.

Built to Last

Durability is a primary feature of the PME-RM70, which is crafted with premium materials to withstand the rigors of heavy use on demanding job sites. This jumping jack tamper is built for long-lasting performance, making it suitable for applications such as subgrade preparation, retaining wall bases, and roadway repairs, delivering reliable results every time.

Applications

- Trench Compaction for Utility and Pipeline Installation

- Foundation and Footing Preparation

- Subgrade and Base Layer Compaction

- Retaining Wall Footings

- Asphalt Patchwork and Repair

- Cohesive and Mixed Soil Compaction (e.g., clay, silt)

- Soil Stabilization for Landscaping Projects

- Confined or Narrow Space Compaction

With its powerful tamping force, reliable engine options, and durable construction, the PME-RM70 Jumping Jack Tamper is designed to meet the needs of construction professionals and rental providers, offering unmatched efficiency and reliability in soil compaction.

Key Specifications

| Model | Jumping Jack Tamper PME-RM70 |

|---|---|

| Engine | Honda GXR120; Robin EH12-2D; Loncin LC165F-3H |

| Engine type | Air-cooled, single cylinder, 4-stroke, petrol engine |

| Fuel tank [L] | 2.8 |

| Leap height [mm] | 85 |

| Frequency [VPM] | 690 |

| Tamping force [KN] | 14 |

| Plate size (LxW) [cm] | 345x285 |

| N.W./G.W. [kg] | 75/85 |

| Package (LxWxH) [cm] | 75x43x110 |

ADVANTAGE

Reinforced Fuel Tank

The fuel tank is built from impact-resistant materials with secure fittings, ensuring reliable fuel storage and preventing leakage under demanding work conditions.

Robust Engine

Equipped with a powerful, reliable engine from renowned brands, ensuring smooth performance with low noise, minimal maintenance, and fuel efficiency.

Advanced Shock Absorption System

Enhanced shock-absorbing design significantly reduces vibration to the operator’s hands, providing a comfortable and controlled operation experience.

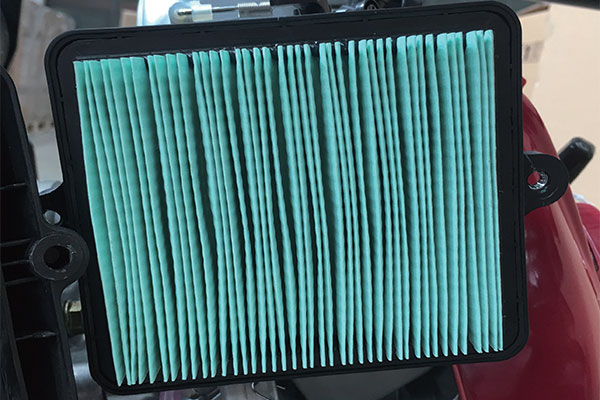

Efficient Air Purification System

A sophisticated air filter system effectively traps dust and debris, keeping the engine cleaner and reducing maintenance needs for extended performance life.

Polyurethane Folding Bellow

High-strength, flexible polyurethane bellow offers improved durability and longevity, resisting cracking and deformation even under heavy-duty use.

Durable Baseplate

A reinforced baseplate built from high-quality steel, designed for maximum stability and optimal compaction efficiency on various terrains.

QUESTIONS & ANSWERS

Jumping Jack Tampers are most effective on cohesive soils, like clay, where their high impact force can achieve deep compaction.

A jumping jack tamper is better suited for confined spaces and cohesive soils, while a roller compactor is ideal for larger areas with granular soils.

Some models are designed to minimize emissions, and electric options are available for environmentally sensitive projects.

Electric models are powerful, though gas models generally offer higher compaction force.

Using electric models and wearing noise-canceling ear protection can help reduce the impact of noise during operation.

Yes, jumping jack tampers can work on gravel, although plate compactors might be more effective for loose gravel.

Other Similar Products

Concrete Saw PME-Q350

Road Saw PME-Q300

Ride On Vibro Roller PME-R6000

Road Roller Compactor PME-R3500

Construction Road Roller PME-R3000

Double Drum Road Roller PME-R2500

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Tamping Rammer

Tamping rammers play a vital role in modern construction, widely used for their efficiency in compacting soil, gravel, and other granular materials. Known for their high-impact motion, tamping rammers stabilize soil, providing strong foundations for roads, pathways, and buildings. providing the compacted surfaces necessary for various building applications. Their powerful impact force and versatility make them a top choice for contractors and builders alike, ensuring strong and reliable foundations in every project.

The Ultimate Guide to Jumping Jack Tampers

Jumping Jack Tampers, also known as rammers or compaction tampers, are powerful tools designed for soil compaction across a variety of terrains and project types. Their primary function is to compress soil, sand, or gravel, making the ground more stable for foundations, roads, and landscaping. In this guide, we’ll cover every aspect of these indispensable tools, from understanding their structure and function to choosing the best model for your needs.

1. What is a Jumping Jack Tamper?

Jumping Jack Tampers are compaction tools primarily used in construction and landscaping to create firm, stable surfaces. Unlike plate compactors, which apply even compaction across a wide area, jumping jack tampers are smaller and designed to penetrate and compact soil more deeply, making them ideal for narrow trenches or areas with cohesive soils like clay.

1.1 History and Development of Jumping Jack Tampers

Jumping Jack Tampers evolved as specialized tools to address the limitations of traditional hand tamping and mechanical plate compactors. Originally developed to tackle jobs requiring intensive, deep soil compaction, early models were simple piston-driven devices. Over time, innovations in engine design, material quality, and ergonomics led to the highly efficient tampers used today, making them a staple in construction.

1.2 Purpose and Functionality

The core purpose of a jumping jack tamper is to produce high-impact blows that condense soil layers, enhancing stability for structures built on top. They excel in narrow, confined areas and perform especially well with cohesive soils, where plate compactors might fail to penetrate deeply.

2. Key Components of a Jumping Jack Tamper

Jumping Jack Tampers comprise several critical parts, each contributing to the tool’s powerful compaction capabilities.

2.1 Engine Types

Most jumping jack tampers run on either gasoline or diesel engines. Gas-powered tampers are popular for their portability and ease of refueling, while diesel models offer superior torque for heavy-duty jobs. Some newer models even utilize battery-powered engines, which can reduce emissions and noise but may be less powerful.

2.2 Compaction Shoe and Plate

The compaction shoe, located at the base, is the part that directly contacts the ground. This heavy, durable plate drives the compaction force into the soil. Shoes vary in width, with smaller shoes offering precise compaction for trenches and larger shoes covering broader surfaces.

2.3 Fuel and Power Sources

While gas is still the most common fuel type, electric tampers are growing in popularity, especially for projects in noise-sensitive or indoor areas. Fuel efficiency is a critical factor for those working on large projects, as fuel costs can add up significantly.

3. How Jumping Jack Tampers Work

Jumping Jack Tampers create compaction by using a percussive mechanism that pounds the ground in rapid, repeated strokes. The result is a dense, stable soil layer.

3.1 Mechanical Process

The engine drives a piston that lifts and drops the compaction shoe repeatedly. This motion produces a high level of impact energy directed into the ground, ensuring deep soil penetration and increased density.

3.2 Soil Compaction Techniques

Proper compaction depends on moving the tamper steadily and evenly. Operators typically guide the tamper in a controlled, rhythmic motion, avoiding over-compaction in any single area. Adjusting speed based on soil type and moisture content is essential for optimal results.

4. Types of Jumping Jack Tampers

Different types of jumping jack tampers cater to various needs, with choices based on fuel, size, and power.

4.1 Gas-Powered vs. Electric Models

Gas-powered models are generally more robust and can be used in remote areas, while electric models offer quieter operation and are suitable for indoor or noise-restricted environments.

4.2 Lightweight vs. Heavy-Duty Models

Lightweight tampers are easier to maneuver and ideal for small projects, while heavy-duty models offer higher impact energy for large-scale construction and demanding soil types.

5. Applications of Jumping Jack Tampers

From construction to landscaping, jumping jack tampers are widely used for tasks requiring thorough soil compaction.

5.1 Construction and Roadwork

In road construction, jumping jack tampers create stable foundations, reducing the risk of pavement cracking and settlement. They’re also indispensable for trench work, allowing workers to compress soil in tight spaces.

5.2 Landscaping and Home Projects

Jumping jack tampers help create stable bases for patios, walkways, and retaining walls. Their portability and versatility make them ideal for smaller projects where deep soil compaction is essential.

5.3 Industrial Applications

In industrial applications, tampers provide critical compaction for pipelines, electrical lines, and other buried infrastructure, ensuring durability and reducing the risk of soil erosion.

6. Advantages of Using Jumping Jack Tampers

These tampers offer several advantages, from cost-efficiency to ease of use.

6.1 Efficiency and Performance Benefits

Jumping jack tampers deliver high impact energy in compact areas, saving time and increasing the stability of foundations. Their vertical motion also minimizes displacement of materials, keeping compaction focused.

6.2 Cost-Effectiveness for Large Projects

When used correctly, jumping jack tampers can eliminate the need for additional compaction, reducing labor costs and project timelines.

7. Comparing Jumping Jack Tampers to Plate Compactors

While both tools are used for compaction, jumping jack tampers and plate compactors serve distinct purposes.

7.1 Pros and Cons of Each Tool

Jumping jack tampers excel in confined spaces and cohesive soils, while plate compactors are better for larger, open areas. Tampers offer more impact per square inch, making them ideal for deeper compaction.

7.2 Choosing the Right Equipment for the Job

Consider soil type, project size, and site accessibility. For large, open areas, a plate compactor is likely best. For trenches or cohesive soils, a jumping jack tamper is the preferred choice.

8. How to Choose the Right Jumping Jack Tamper

Selecting the ideal tamper depends on your specific needs and budget.

8.1 Factors to Consider

Consider engine type, fuel efficiency, impact energy, and shoe size. For frequent use, durability and maintenance requirements are also key factors.

8.2 Top Brands and Models

Brands like Wacker Neuson, Multiquip, and Honda offer top-performing models. Each brand has its strengths, with Wacker Neuson known for durability, Multiquip for performance, and Honda for reliability.

9. Operating a Jumping Jack Tamper Safely

Safety is paramount when using high-impact machinery like jumping jack tampers.

9.1 Safety Gear and Best Practices

Operators should wear protective gear, including gloves, ear protection, and safety glasses. Ensuring the tamper is on stable ground before operation prevents accidental tipping.

9.2 Common Mistakes to Avoid

Common errors include over-compacting, which can lead to soil instability, and improper handling of fuel or power sources, which can cause damage.

10. Maintenance Tips for Longevity

Proper maintenance can extend the lifespan of a jumping jack tamper significantly.

10.1 Routine Checks and Inspections

Regularly inspect the tamper for wear on the compaction shoe, engine parts, and fuel lines. Checking oil and air filters before use can prevent major issues.

10.2 Storage and Care

Store the tamper in a dry, covered area to prevent rust. Fuel should be drained if the machine is stored for extended periods.

11. Troubleshooting Common Issues

Understanding common problems and their solutions can save time and money.

11.1 Engine and Power Problems

If the engine won’t start, check the fuel level and spark plug. Overheating may indicate low oil or an obstruction in the air intake.

11.2 Vibrations and Compaction Plate Issues

Unusual vibrations could signal loose bolts or a worn-out shoe. Addressing these issues promptly can prevent further damage.

Conclusion

Jumping Jack Tampers are essential tools for anyone needing thorough soil compaction in tight or challenging areas. With a variety of models available, there’s a tamper for every project, from heavy-duty construction to home landscaping. By understanding how to select, operate, and maintain these machines, users can achieve reliable, lasting results that support strong and stable foundations for all types of structures.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.