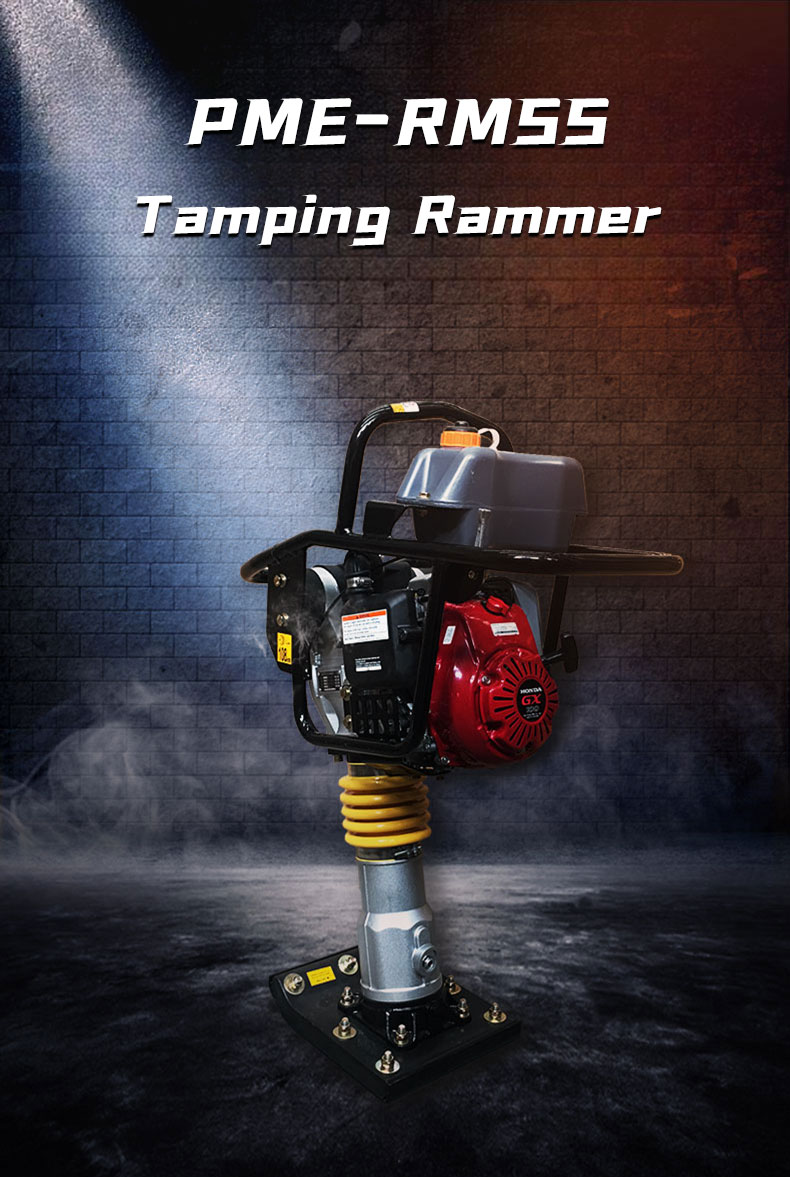

Earth Rammer PME-RM55

When you are looking for a earth rammer, we can assist you in selecting the most suitable tamping rammer for your business.

Earth Rammer PME-RM55

The PME-RM55 Earth Rammer is a robust, high-performance machine designed for contractors and construction professionals who need powerful compaction for heavy-duty tasks. Featuring a 265 x 340 mm foot and delivering a strong tamping force of 13 KN, it reaches a leap height of 70 mm, making it a highly effective tool for compacting dense soils and subgrades.

Powerful Performance

The PME-RM55 is equipped with either a reliable Honda GX100 or Robin EH09 engine, ensuring consistent power and efficiency. The air-cooled, single-cylinder, 4-stroke petrol engine is designed for demanding applications, with a fuel tank capacity of 2.8 L that allows for extended operation on the job. Operating at a frequency of 695 VPM, this earth rammer is well-suited for compacting even the most challenging soils, from clay-rich areas to tightly compacted bases.

Versatile Application

Designed for versatility in confined spaces, the PME-RM55 Earth Rammer is an ideal solution for compacting cohesive soils like clay, silt, and mixed types. Its powerful impact and maneuverability make it perfect for foundation preparation, trench work, and other situations where precision compaction is critical. This earth rammer is an asset for contractors, equipment rental companies, and anyone needing high compaction power in challenging environments.

Built to Last

Durability is central to the PME-RM55’s design. Constructed from premium materials, it’s built to withstand the demands of continuous use, even on the toughest job sites. Its robust design ensures reliable performance for applications such as base preparation, subgrade compacting, and pipeline installation, providing peace of mind and dependable results for every project.

Applications

- Foundation and Footing Compaction

- Trench Compaction for Pipelines

- Subgrade and Base Layer Preparation

- Retaining Wall Footing

- Roadway and Pavement Base Work

- Cohesive Soil Compaction (e.g., clay, silt)

- Backfill and Soil Stabilization

- Patchwork and Repair on Asphalt

- Confined or Narrow Space Compaction

With its powerful tamping force, wide plate, and durable build, the PME-RM55 Earth Rammer is engineered to tackle the most demanding compaction tasks, making it an invaluable tool for professional contractors and rental services alike.

Key Specifications

| Model | Earth Rammer PME-RM55 |

|---|---|

| Engine | Honda GX100; Robin EH09 |

| Engine type | Air-cooled, single cylinder, 4-stroke, petrol engine |

| Fuel tank [L] | 2.8 |

| Leap height [mm] | 70 |

| Frequency [VPM] | 695 |

| Tamping force [KN] | 13 |

| Plate size (LxW) [cm] | 265x340 |

| N.W./G.W. [kg] | 58/68 |

| Package (LxWxH) [cm] | 68x35x103 |

ADVANTAGE

Reinforced Fuel Tank

The fuel tank is built from impact-resistant materials with secure fittings, ensuring reliable fuel storage and preventing leakage under demanding work conditions.

Robust Engine

Equipped with a powerful, reliable engine from renowned brands, ensuring smooth performance with low noise, minimal maintenance, and fuel efficiency.

Advanced Shock Absorption System

Enhanced shock-absorbing design significantly reduces vibration to the operator’s hands, providing a comfortable and controlled operation experience.

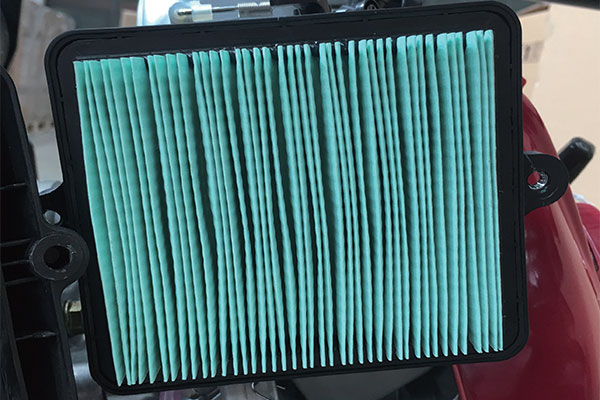

Efficient Air Purification System

A sophisticated air filter system effectively traps dust and debris, keeping the engine cleaner and reducing maintenance needs for extended performance life.

Polyurethane Folding Bellow

High-strength, flexible polyurethane bellow offers improved durability and longevity, resisting cracking and deformation even under heavy-duty use.

Durable Baseplate

A reinforced baseplate built from high-quality steel, designed for maximum stability and optimal compaction efficiency on various terrains.

QUESTIONS & ANSWERS

An Earth Rammer delivers high-impact force, making it ideal for cohesive soils and projects that require deep, uniform compaction. Unlike vibratory compactors, which rely on vibrations to compact soil, Earth Rammers provide direct impact, offering better results for dense and cohesive soils.

Earth rammers are ideal for road construction, building foundations, and landscaping work that requires concentrated soil compaction.

Yes, but it’s essential to ensure the soil isn’t too wet, as this can hinder compaction. Slightly moist soil generally compacts better than overly dry or muddy soil. If the soil is very wet, it’s best to let it dry out before compacting to achieve the desired density and stability.

Operators should wear protective gear such as gloves, ear protection, and steel-toe boots. Inspect the work area for debris or uneven ground, and follow the manufacturer’s instructions for safe operation. Proper stance and control of the handle are crucial for avoiding injuries during use.

For occasional, small projects, renting an Earth Rammer can be cost-effective. However, for ongoing or frequent projects, purchasing might offer better value and convenience in the long run.

Other Similar Products

Concrete Saw PME-Q350

Road Saw PME-Q300

Ride On Vibro Roller PME-R6000

Road Roller Compactor PME-R3500

Construction Road Roller PME-R3000

Double Drum Road Roller PME-R2500

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Tamping Rammer

Tamping rammers play a vital role in modern construction, widely used for their efficiency in compacting soil, gravel, and other granular materials. Known for their high-impact motion, tamping rammers stabilize soil, providing strong foundations for roads, pathways, and buildings. providing the compacted surfaces necessary for various building applications. Their powerful impact force and versatility make them a top choice for contractors and builders alike, ensuring strong and reliable foundations in every project.

Why Should You Use an Earth Rammer for Compaction?

Soil compaction is a fundamental step in most construction projects, providing stability and structure to the foundation. An Earth Rammer is a powerful tool that enhances soil compactness, making it more durable and suitable for supporting heavy loads. In this article, we’ll explore the key benefits, usage methods, safety practices, and frequently asked questions to help you understand why an Earth Rammer is an essential choice for compaction needs.

1. Introduction

What is an Earth Rammer?

An Earth Rammer, also known as a tamper, is a heavy-duty compaction tool commonly used in construction to compress and stabilize soil. Unlike other types of compactors, Earth Rammers focus on producing high-impact force on the ground, ensuring deeper and denser compaction. This makes them particularly valuable for heavy-duty projects that require strong and stable foundations, such as building roads, foundations for structures, and even garden landscaping. Earth Rammers are characterized by a flat, heavy base and a handle for easy control, delivering a direct and powerful force into the ground.

Importance of Soil Compaction in Construction

Soil compaction is a crucial step in construction for various reasons. It strengthens the soil, reduces its permeability, and prevents uneven settling. When soil is properly compacted, it becomes more capable of bearing heavy loads, minimizing the risk of foundational shifts or soil erosion over time. This process ensures that the ground can support structures, preventing structural issues such as cracking or sinking. Given these benefits, compaction is essential across residential, commercial, and infrastructure projects, and Earth Rammers are a top choice for achieving high-quality compaction results.

Overview of Earth Rammers for Compaction

Earth Rammers are valued in the construction industry for their efficiency and effectiveness in compacting different types of soils. Their design allows them to deliver powerful blows to the ground, enabling them to handle even tough and coarse soils. Whether working with sandy, clayey, or silty soils, an Earth Rammer’s impact makes it possible to achieve dense, uniform compaction. Because of their versatility and strength, Earth Rammers have become a go-to tool for contractors looking to create stable bases quickly and with minimal effort.

2. How Earth Rammers Work

Basic Mechanisms and Functions

Earth Rammers operate on the principle of impact compaction. They’re equipped with a flat, wide plate that strikes the ground in rapid, repetitive motions. This force compacts the soil by reducing the air pockets between particles, creating a denser and more stable ground layer. Some models are powered by gasoline or diesel engines, while others operate manually. The machine’s design ensures that each impact covers a substantial area, allowing operators to compact soil efficiently without needing excessive passes.

Key Components of an Earth Rammer

Earth Rammers consist of a few essential parts: the plate, handle, engine (in motorized versions), and weight. The plate is the flat base that makes contact with the ground, while the handle provides the operator with control over the machine. For motorized versions, the engine powers the repetitive impact motion, enhancing force. This design enables Earth Rammers to deliver consistent impact pressure, ensuring reliable results across different soil types and project requirements.

Types of Earth Rammers and Their Applications

Earth Rammers come in various types tailored to specific compaction needs. Some models are larger and more powerful, suited for heavy-duty applications like road building and industrial projects. Other, smaller models are ideal for residential landscaping and minor construction tasks. Understanding the range of Earth Rammer options helps contractors choose the right tool for their specific project, balancing power, efficiency, and maneuverability to ensure optimal compaction results.

3. Benefits of Using an Earth Rammer

Enhancing Soil Stability

One of the primary benefits of using an Earth Rammer is that it significantly enhances soil stability. By compacting the soil to remove air pockets, an Earth Rammer increases the density of the ground, which improves its ability to bear loads and resist erosion. This stability is especially critical in areas prone to shifting soils or heavy rainfall, where uncompact soil could lead to foundational issues over time.

Reducing Structural Risks

Using an Earth Rammer to compact soil can help reduce structural risks by creating a firm base for construction. Compacted soil is less likely to settle unevenly, which means fewer chances of cracks forming in foundations, walkways, or pavements. With an Earth Rammer, contractors can ensure that the ground remains firm and stable, helping to protect against the long-term costs associated with foundation repair.

Improving Load-Bearing Capacity

Another key advantage of an Earth Rammer is its ability to improve the soil’s load-bearing capacity. This is essential for projects like roads, parking lots, and driveways, where the ground must withstand substantial weight. By enhancing the compactness of the soil, Earth Rammers make it capable of supporting heavy loads without shifting or sinking. This improvement in load-bearing capacity is essential for safety and durability in construction.

4. Types of Compaction Equipment

Earth Rammers Compared to Plate Compactors

While Earth Rammers and plate compactors both aim to compact soil, they operate differently and are suited for different tasks. Plate compactors rely on vibration to compact the ground, making them ideal for granular soils like sand and gravel. In contrast, Earth Rammers use impact, making them effective for a broader range of soil types, including cohesive soils like clay. For projects where deep compaction is needed, Earth Rammers are often preferred over plate compactors.

Vibratory Rollers vs. Earth Rammers

Vibratory rollers are commonly used for large-scale road construction projects. These machines are larger than Earth Rammers and rely on a combination of vibration and weight to compact soil over extensive areas. While they’re highly effective for large projects, they lack the maneuverability of Earth Rammers, which makes Earth Rammers a better choice for smaller, more precise applications where targeted compaction is necessary.

Jumping Jack Compactors: Pros and Cons

Jumping Jack compactors are another form of impact-based compaction equipment. They’re typically more lightweight than Earth Rammers and are used for narrow or confined spaces, such as trenches. However, while Jumping Jacks are easier to maneuver in tight spaces, they’re generally less powerful than Earth Rammers and may require more passes to achieve deep compaction. For projects requiring substantial force, an Earth Rammer is often the more efficient option.

5. Applications of Earth Rammers

Residential Construction: Driveways and Walkways

In residential construction, Earth Rammers are commonly used to prepare ground for driveways, walkways, and patios. By compacting the soil beneath these surfaces, Earth Rammers help prevent uneven settling and cracking. A stable, compacted base also makes it easier to lay paving stones or concrete, ensuring a durable and visually appealing result that can withstand everyday use and weather exposure.

Commercial Construction: Parking Lots and Roads

Earth Rammers play a crucial role in commercial projects, particularly for parking lots and roads. These applications require a high degree of soil stability to support heavy vehicles and high traffic. By using an Earth Rammer, contractors can create a compact and uniform soil foundation, which is critical for the longevity and safety of the surface above. A well-compacted base reduces the likelihood of cracks, potholes, and other surface damage, ensuring a longer-lasting infrastructure.

Landscaping and Garden Projects

Beyond heavy construction, Earth Rammers are also valuable in landscaping and garden projects. They’re often used to compact soil for garden beds, terraces, and retaining walls. In these settings, an Earth Rammer provides a stable foundation for plants, pathways, and decorative features. By ensuring the soil is properly compacted, Earth Rammers help reduce erosion and promote healthier plant growth by preventing waterlogging and nutrient loss in the soil.

6. Safety Considerations

Safe Operation Practices

Operating an Earth Rammer safely is essential for avoiding injuries and ensuring effective compaction. Operators should always wear appropriate safety gear, including gloves, protective footwear, and hearing protection. Additionally, maintaining a steady stance and controlling the handle carefully helps prevent accidental slips or mishaps. It’s also important to inspect the area for debris or obstacles before operating the machine to avoid tripping or damage to the equipment.

Safety Gear and Equipment Needed

To ensure safe operation, several pieces of safety gear are recommended. This includes a hard hat, eye protection, earplugs or earmuffs, gloves, and steel-toe boots. Proper protective gear not only safeguards operators from potential accidents but also helps mitigate the impact of prolonged exposure to vibration and noise from the Earth Rammer.

Regular Maintenance for Safety

Maintenance is key to ensuring an Earth Rammer operates safely and efficiently. Regularly inspecting and cleaning the machine, checking for loose parts, and ensuring proper lubrication of moving components can prevent malfunctions during operation. Following manufacturer guidelines for maintenance reduces wear and tear and extends the lifespan of the equipment, providing a safer experience for the operator.

7. Factors to Consider When Choosing an Earth Rammer

Soil Type and Moisture Levels

Different soil types respond differently to compaction, so it’s essential to match your Earth Rammer to the conditions of your project site. For example, cohesive soils like clay may require a heavier, impact-driven Earth Rammer to achieve effective compaction, while sandy or granular soils might work well with a lighter model. Additionally, moisture levels can impact compaction. Soil that’s too wet or dry can be difficult to compact effectively, so choosing the right machine and adjusting moisture levels as needed can make a big difference in the final result.

Project Size and Frequency

When selecting an Earth Rammer, consider the size and scale of your project. For large projects, such as road construction or extensive landscaping, a high-powered, fuel-efficient Earth Rammer might be the best choice. Conversely, for smaller or infrequent projects, a lightweight or portable Earth Rammer may be more practical. It’s also worth considering whether renting or buying the equipment is more cost-effective based on how often you’ll use it.

Portability and Ease of Use

Portability and ease of use are crucial factors, particularly if you need to move the Earth Rammer across multiple sites. Smaller, lighter models are easier to transport and maneuver, making them ideal for residential projects. Larger, heavier models provide more force but may require transportation support. Opt for a model that balances ease of use with the power required for your specific tasks to maximize efficiency and minimize fatigue.

8. Environmental Impact

Reducing Soil Erosion

Proper compaction using an Earth Rammer plays a key role in preventing soil erosion. Compacted soil is more resistant to wind and water erosion, helping to maintain the integrity of the construction site and surrounding areas. This is particularly beneficial for projects near water bodies or sloped terrain, where soil erosion could have negative environmental effects. By stabilizing the ground, Earth Rammers contribute to greener construction practices by reducing the need for erosion-control measures post-construction.

Minimizing Vibration and Noise Pollution

While Earth Rammers are powerful machines, many models are designed with noise reduction and low-vibration features to reduce environmental impact. Vibration isolation technology not only minimizes strain on the operator but also reduces disturbances in urban or residential settings. Choosing an Earth Rammer with these features can be a significant advantage for projects in populated areas, where noise and vibrations could disrupt nearby residents or businesses.

Green Construction Practices

Incorporating an Earth Rammer into a project can support green construction practices by reducing the need for additional structural support materials, which can be costly and environmentally taxing. By compacting soil efficiently, Earth Rammers reduce the need for materials like concrete or gravel in creating stable bases, which in turn lowers the project’s environmental footprint. Additionally, many modern Earth Rammers are built with fuel-efficient engines or electric models, offering a more eco-friendly option for sustainable construction.

9. Step-by-Step Guide to Using an Earth Rammer

Preparing the Site for Compaction

Proper site preparation is essential before using an Earth Rammer. Start by clearing any debris, rocks, or vegetation from the area to ensure a smooth and even compaction process. Check the soil moisture level, as compacting overly dry or wet soil can be less effective. If necessary, water the soil lightly to achieve the ideal moisture level for compaction. Mark out the area to be compacted to maintain consistent coverage and avoid overlap or missed spots.

How to Operate an Earth Rammer Effectively

To operate an Earth Rammer, position the machine on the prepared surface, and use a firm grip on the handle to maintain control. For motorized models, start the engine following the manufacturer’s instructions, and guide the machine in steady, overlapping passes across the area. Avoid forcing the Rammer to move too quickly, as slower, deliberate movements lead to more thorough compaction. Maintain a consistent pattern, covering each section of the ground to ensure uniform compaction throughout.

Post-Compaction Care

Once the area is compacted, inspect the surface for any uneven spots or loose areas that may need additional passes with the Earth Rammer. After use, clean the machine thoroughly, removing any soil or debris from the plate and other components. Regular cleaning and maintenance after each project can prevent wear and tear and ensure your Earth Rammer is ready for the next use. This post-compaction care helps maintain the quality and durability of both the compacted surface and the machine itself.

10. Maintenance Tips for Earth Rammers

Regular Inspection and Cleaning

Keeping your Earth Rammer in top condition requires regular inspections. Before each use, check for any loose bolts, cracks, or wear on essential parts like the plate and handle. Regular cleaning of the machine, particularly around the plate and engine, helps prevent the build-up of dirt or debris, which can affect performance over time. Simple upkeep practices, such as wiping down the machine and lubricating parts, can extend its lifespan and maintain efficient operation.

Engine and Part Lubrication

For motorized Earth Rammers, proper engine maintenance is essential. Follow the manufacturer’s guidelines for oil changes, fuel quality, and lubrication to keep the engine running smoothly. Lubricate moving parts, like the joints and mechanisms that enable the plate to deliver impact, as this reduces friction and wear. Using high-quality oils and lubricants also helps prevent overheating and mechanical breakdowns, particularly during long or heavy-duty use.

Storage Best Practices

Proper storage is key to preserving your Earth Rammer’s longevity, especially in harsh climates. Store the machine in a cool, dry place, preferably in an area free from dust and moisture. Avoid leaving it in direct sunlight or damp conditions, as extreme temperatures and humidity can cause rust or damage to the components. If storing for an extended period, empty the fuel tank to prevent corrosion and cover the machine to shield it from dust and debris.

11. Cost Analysis of Earth Rammers

Initial Purchase Costs

The upfront cost of an Earth Rammer varies depending on its size, power, and features. While basic models may be more affordable, heavy-duty or motorized Earth Rammers can represent a significant investment. For construction companies or frequent users, purchasing a high-quality Earth Rammer may be more cost-effective in the long run. Assessing the specific needs of your projects and budget can help you make the right purchase decision.

Long-Term Maintenance and Operational Costs

In addition to the purchase price, long-term costs for Earth Rammers include fuel, maintenance, and occasional part replacements. Regular upkeep helps avoid costly repairs, so it’s wise to allocate a budget for routine maintenance. Fuel efficiency is another factor to consider, as more fuel-efficient models reduce operational costs over time. Choosing a reliable brand or model with low maintenance requirements can help minimize these long-term expenses.

Renting vs. Buying an Earth Rammer

If you only need an Earth Rammer for a one-time project or occasional use, renting might be a more economical choice. Rental options are available at construction equipment providers, typically on a daily or weekly basis, which can provide significant savings. However, for frequent or long-term projects, purchasing an Earth Rammer offers greater value and convenience, allowing you to access the equipment whenever needed without repeated rental fees.

12. Common Misconceptions About Earth Rammers

Earth Rammers Only Work on Hard Soils

One common misconception is that Earth Rammers are only effective on hard or rocky soils. In reality, Earth Rammers work well across a range of soil types, including sandy and clayey soils. Their high-impact design makes them versatile for compacting different soil compositions, allowing for stable and secure foundations regardless of the soil characteristics.

They’re Too Heavy for Small-Scale Projects

Another myth is that Earth Rammers are only suitable for large-scale projects due to their weight and power. While heavier models are available for industrial use, there are also lighter, more compact models designed for residential or small-scale projects. These models offer the same compaction benefits in a more manageable size, making Earth Rammers suitable for a wide variety of applications, from home landscaping to minor construction.

Earth Rammers Are Difficult to Operate

Although Earth Rammers may appear challenging to handle, they are actually user-friendly once you understand the basic controls. Many models are designed with ergonomic handles and vibration-damping features, making them easier to control. With a bit of practice, most operators can achieve effective compaction results with minimal strain, especially when following proper usage guidelines.

This comprehensive guide covers the essential aspects of Earth Rammers, from their functionality and benefits to detailed usage and maintenance tips. Whether you’re working on a residential project or a large-scale construction site, understanding how to select and operate an Earth Rammer can ensure optimal compaction results and long-term stability for any project.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.