Scarifying Machine

Description

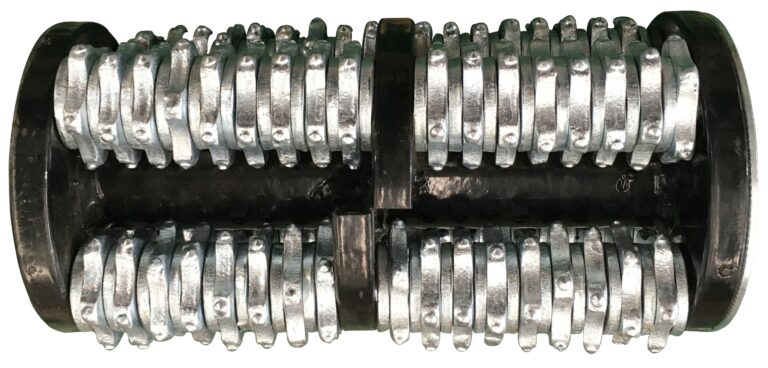

With scarifying, cutters are loosely fitted on lateral shafts which are then placed inside a drum housing. The drum is placed inside the machine and once the machine is switched on, the rotating drum generates centrifugal force which throws the cutter at the surface, causing a mechanical cutting action. Dust and contaminants are moved to a dedicated dust collector. This makes the process almost dust-free in operation.

Features

- Scarifying depth is adjustable

- Front mounting lifting handle for easy transportation

- Heavy duty shock buffer mounts to reduce vibration toward handle and engine

- Outlet dust-proof device

- Sealed bearing extend usage life

- Asphalt blades and cement blade as optional

| Model | PME-SM20H |

|---|---|

| Engine | Honda GX160 |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine |

| Displacement [cc] | 163 |

| Engine power [HP] | 5.5 |

| Rated power [KW] | 3.05 |

| Speed [RPM] | 3600 |

| Starting system | Manual start |

| Employed fuel | 93# |

| Employed oil | 10W-30 |

| Fuel tank capacity [L] | 3.6 |

| Oil tank capacity [L] | 0.65 |

| Working width [cm] | 20 |

| Scarifying depth [mm] | 1.6-3.0 |

| Milling spindle QTY | 4 |

| Efficiency [m2/h] | 70 |

| N.W./G.W. [kg] | 64/69 |

| Package (LxWxH) [cm] | 104x44x97 |

| Model | PME-SM25H |

|---|---|

| Engine | Honda GX390 |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine |

| Displacement [cc] | 389 |

| Engine power [HP] | 13 |

| Rated power [KW] | 6.6 |

| Speed [RPM] | 3600 |

| Starting system | Manual start |

| Employed fuel | 93# |

| Employed oil | 10W-30 |

| Fuel tank capacity [L] | 6.5 |

| Oil tank capacity [L] | 1.1 |

| Working width [cm] | 25 |

| Scarifying depth [mm] | 2-5 |

| Milling spindle QTY | 4 |

| Efficiency [m2/h] | 100 |

| N.W./G.W. [kg] | 115/125 |

| Package (LxWxH) [cm] | 97x58x109 |

Maintenance

Scarifying machine periodic maintenance schedule

| Time/Contents | Daily Before Starting | After First 5 Hrs. | After First 50 Hrs. | Every Week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

|---|---|---|---|---|---|---|

| Check fule level | √ | |||||

| Check oil level of machine | √ | |||||

| Check fule line and fittings for cracks or leaks | √ | |||||

| Check and tighten engine cylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Check V-belt | √ | |||||

| Clean engine cooling fins | √ | |||||

| Check and clean spark plug gap | √ | |||||

| Check and clean spark plug | √ | |||||

| Clean recoil starter | √ | |||||

| Clean engine muffler and exhaust port | √ |

Note: If engine performance is poor,please check,clean and replace air filter elements as needed.

Engine periodic maintenance schedule

| Each use | First month or 20 hours | Every 3 months or 50 hours | Every 6 months or 100 hours | Every year or 300 hours | ||

|---|---|---|---|---|---|---|

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √☆ | |||||

| Sediment Cup | √ | |||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Spark arrester(optional parts) | Clean | √ | ||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel tank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

☆ Replace the paper element type only.

(1)Service more frequently when used in dusty areas.

(2)These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures.

Performed at every indicated month or operating hour interval, whichever comes first.