Vibratory Roller PME-R800

When you are looking for a vibratory roller, we can assist you in selecting the most suitable compactor roller for your business.

Vibratory Roller PME-R800

The PME-R800 Vibratory Roller is a high-performance solution for demanding compaction tasks, engineered to deliver exceptional results across a range of construction applications. Featuring dual rollers with dimensions of 426 mm in diameter and 700 mm in width, this roller offers powerful double-wheel vibration and superior handling, making it ideal for large-scale roadwork, foundation preparation, and infrastructure projects.

Powerful Performance

Powered by either a Honda GX390 or ChangFa CF180FE engine, the PME-R800 delivers reliable and robust power for heavy-duty compaction tasks. The air-cooled, 4-stroke engine ensures consistent performance and efficiency, even under continuous operation. With a centrifugal force of 20 KN and a vibration frequency of 70 Hz, the PME-R800 is built to handle asphalt, gravel, and soil compaction with ease. Its nominal amplitude of 0.5 mm ensures deep and effective compaction for creating stable, durable surfaces.

Versatile Application

The PME-R800 excels in a wide range of applications, from road construction and repair to foundation and subgrade preparation. Its automatic vibration system activates double-wheel vibration for enhanced efficiency and uniform results. Designed to tackle challenging terrains, the PME-R800 features a gradeability of 30°, allowing it to perform smoothly on steep slopes and uneven surfaces. With a travel speed of 0-4 km/h, operators can maneuver the roller with precision, ensuring excellent results in both confined and open spaces.

Built to Last

Constructed with durability in mind, the PME-R800 is made from premium materials to withstand the rigors of heavy-duty use. The 25L water tank capacity supports effective compaction by reducing friction and ensuring a smooth finish. The hydraulic pump and motor system offer seamless operation, while the machine’s robust design minimizes maintenance and downtime. Whether working on large infrastructure projects or smaller-scale repairs, the PME-R800 provides dependable performance in any environment.

Applications

- Road Construction and Maintenance

- Asphalt, Gravel, and Soil Compaction

- Foundation and Subgrade Preparation

- Compaction in Tight or Confined Areas

- Large-Scale Infrastructure Projects

- Pathways, Driveways, and Landscaping

- Sloped Terrain Compaction (Gradeability: 30°)

- Soil Stabilization and Structural Work

With its powerful engine, double-wheel vibration system, and rugged construction, the PME-R800 Vibratory Roller is the ultimate choice for contractors and professionals who demand reliable and efficient compaction. Whether for roadwork or foundation preparation, this roller delivers exceptional results in even the most challenging conditions.

Key Specifications

| Model | Vibratory Roller PME-R800 |

|---|---|

| Engine | Honda GX390/ ChangFa CF180FE |

| Roller size [diameter x width] | 2xφ426x700 mm |

| Drive type | Hydraulic pump, hydraulic motor, double wheels drive |

| Vibration type | Automatic, double wheels vibration |

| Nominal amplitude | 0.5 mm |

| Vibration frequency | 70 Hz |

| Centrifugal force | 20 KN |

| Water tank capacity | 25 L |

| Gradeability | 30° |

| Travel speed | 0-4 km/h |

| N.W./G.W. | 750/770 kg |

| Package size | 135x95x125 cm |

ADVANTAGE

Compact Size

The PME - R800 features a compact design with well - positioned handlebars, enhancing its maneuverability. This enables operators to navigate and control the machine with ease, even in confined spaces.

Powered Engine

Equipped with a robust Changfa engine, the PME - R800 provides reliable and efficient power, ensuring smooth and consistent compaction performance.

Dual Steel Drums

The PME - R800 has two steel drums at the front. These drums collaborate to compact soil, asphalt, and other construction materials more effectively. The dual - drum design guarantees a more uniform compaction surface, particularly on larger areas.

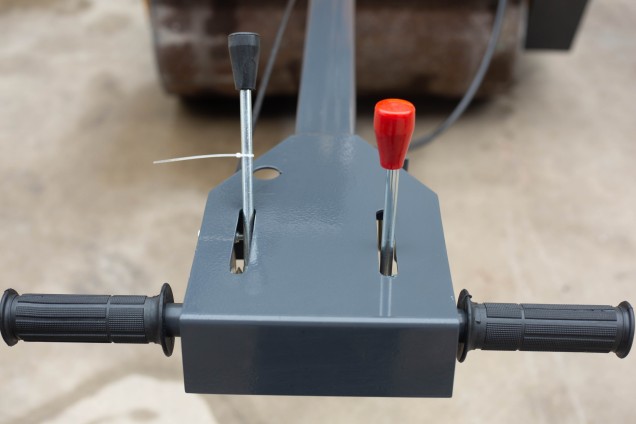

Ergonomic Handle and Controls

The PME - R800 comes with an ergonomic handle and intuitive controls. The handle is designed for operator comfort, and the controls, including levers and buttons, are easily accessible, allowing for precise operation.

Water Tank and Hose

An integrated water tank and hose are included in the PME - R800. This setup is used for wetting the drum, preventing materials from sticking during the compaction process.

Drum with Scraper

The PME - R800 is equipped with a drum featuring a built - in scraper. The scraper effectively removes any material that may adhere to the drum during compaction, ensuring the drum remains clean and efficient. This feature is essential for maintaining the quality of the compaction work.

QUESTIONS & ANSWERS

A vibratory roller is used to compact materials like soil, asphalt, and gravel to achieve stable and durable surfaces in construction and roadwork projects.

Consider factors such as project scale, material type, drum size, frequency settings, and budget to choose the most suitable vibratory roller.

Vibratory rollers are designed for deep, uniform compaction, while plate compactors are best for surface-level tasks.

Unlike other compactors, vibratory rollers combine static weight and vibratory force for deeper and more uniform compaction, making them suitable for diverse applications.

Yes, vibratory rollers are designed to handle various soil types, including granular and cohesive soils, by adjusting frequency and amplitude settings.

Routine maintenance includes inspecting and cleaning the drum, checking hydraulic systems, lubricating parts, and adhering to the manufacturer’s servicing schedule.

Modern models are fuel-efficient and designed to minimize noise and vibration pollution.

Operators should be trained, wear safety gear, and follow guidelines for working on slopes and handling vibrations.

Other Similar Products

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Vibratory Roller

A vibratory roller is a type of heavy construction equipment widely used in the construction and civil engineering industries. It plays a crucial role in compacting various types of soil, asphalt, and other materials to achieve a stable and even surface. This equipment is essential for projects like road construction, airport runways, building foundations, and other large-scale developments requiring a solid base.

Why Choose a Vibratory Roller Over Other Compactors?

Introduction to Vibratory Rollers

What is a Vibratory Roller?

A vibratory roller is a specialized type of compaction equipment designed to compress various materials like soil, asphalt, and gravel. This machine uses vibratory motion to achieve deeper and more uniform compaction, making it indispensable in construction and roadwork projects.

Key Components and Functionality

The vibratory roller comprises critical elements such as a vibrating drum, an engine, and a suspension system. The vibrating drum exerts a combination of static weight and vibratory force to compact materials effectively. Meanwhile, the suspension system minimizes vibrations transmitted to the operator, ensuring smoother handling.

Historical Evolution of Vibratory Rollers

The journey of vibratory rollers began in the mid-20th century, revolutionizing the construction industry with their efficiency. Today’s models integrate advanced technologies for greater performance and sustainability.

Overview of Common Compaction Equipment

Plate Compactors: Features and Use Cases

Plate compactors are a versatile choice for smaller-scale projects like sidewalks, driveways, and landscaping. Their flat base plate vibrates to compact materials, making them ideal for tight spaces and granular soils. However, they lack the power and efficiency needed for larger projects, often requiring multiple passes to achieve desired results.

Rammer Compactors: Pros and Cons

Rammer compactors, also known as tamping rammers, are commonly used for cohesive soils like clay. Their ability to deliver high-impact compaction through a smaller footprint makes them ideal for trenches and confined spaces. Despite their advantages, they are less effective for large-scale projects and can be challenging to operate for extended periods due to their significant recoil and vibrations.

Smooth Drum Rollers vs. Vibratory Rollers

Smooth drum rollers rely solely on their weight to compact materials. While effective on flat surfaces like asphalt, they struggle with uneven or loose soils. In contrast, vibratory rollers combine static weight with vibratory forces, delivering superior compaction depth and uniformity. This dual-action capability makes them more versatile for diverse applications.

Advantages of Vibratory Rollers

Superior Compaction Efficiency

Vibratory rollers are engineered to deliver deep and uniform compaction in fewer passes. Their vibratory motion enhances particle interlock, increasing the density and stability of materials. This efficiency translates to reduced project timelines and lower operational costs.

Cost-Effectiveness in Large Projects

For extensive construction or roadwork projects, vibratory rollers prove highly cost-effective. Their ability to cover large areas quickly reduces labor hours and fuel consumption. Additionally, their versatility across soil types minimizes the need for multiple machines, further saving costs.

Adaptability Across Soil Types

One of the standout features of vibratory rollers is their adaptability. Whether working with granular soils, cohesive materials, or asphalt, these machines adjust frequency and amplitude settings to achieve optimal results. This flexibility ensures consistent compaction quality across diverse conditions.

Reduced Labor Intensity

By combining weight and vibratory force, vibratory rollers significantly reduce the number of passes required for compaction. This feature alleviates operator fatigue and minimizes wear and tear on the equipment, contributing to overall project efficiency.

How Vibratory Rollers Work

Mechanism Behind the Vibratory Action

Vibratory rollers use an eccentric shaft mechanism within the drum to generate vibratory forces. These forces, combined with the roller’s weight, create dynamic pressure that compacts materials deeper and more uniformly than static rollers.

Frequency and Amplitude: Key Parameters

The performance of a vibratory roller hinges on two critical factors: frequency (the number of vibrations per second) and amplitude (the vertical displacement of the drum). Adjusting these parameters allows the operator to tailor the roller’s performance to specific materials and project requirements.

The Role of Weight in Performance

While vibratory motion plays a crucial role, the roller’s weight provides the static force necessary for effective compaction. The combination of static and dynamic forces ensures the roller delivers optimal results for both surface and subsurface compaction.

Comparing Vibratory Rollers with Other Compactors

Compaction Speed: Vibratory Rollers vs. Plate Compactors

When speed is of the essence, vibratory rollers outperform plate compactors. Their ability to cover larger areas in a single pass reduces project timelines significantly. Plate compactors, while precise for small spaces, are no match for the efficiency of vibratory rollers on expansive job sites.

Achieving Uniform Density with Vibratory Rollers

Uniform density is critical for structural stability, especially in road construction. Vibratory rollers excel in achieving this through their dual-action compaction. Other compactors often require additional passes or tools to reach similar levels of uniformity.

Durability and Maintenance Requirements

Vibratory rollers are designed for rugged environments, featuring robust components that withstand intensive use. While they require regular maintenance, their durability often surpasses that of lighter compaction equipment like rammers or plate compactors.

Applications of Vibratory Rollers

Road Construction Projects

Vibratory rollers are indispensable in road construction, where achieving a stable and durable base is critical. These machines compact layers of soil, aggregate, and asphalt efficiently, ensuring the structural integrity of roads. Their ability to handle uneven terrain and varying soil types makes them a preferred choice for highways, urban streets, and rural roads.

Foundation Preparation

Preparing a solid foundation is vital for any construction project, and vibratory rollers excel in this role. By compacting the soil beneath structures like buildings, bridges, and pavements, they prevent future settlement and ensure long-term stability. Their adaptability to different soil conditions enhances their utility across diverse construction scenarios.

Landscaping and Sports Fields

In landscaping, vibratory rollers provide a smooth and compacted surface for lawns, gardens, and recreational areas. For sports fields, these rollers create firm and even surfaces that meet professional standards, ensuring player safety and field durability. Their precision and efficiency are especially valuable in projects requiring high-quality finishes.

Environmental and Safety Considerations

Minimizing Noise and Vibration Pollution

Modern vibratory rollers are designed to reduce noise and vibration emissions, addressing environmental concerns. Features like advanced suspension systems and sound-dampening materials ensure that these machines comply with regulatory standards, making them suitable for projects in urban and residential areas.

Ensuring Operator Safety and Comfort

Safety is a top priority in construction, and vibratory rollers include various features to protect operators. Enclosed cabins, ergonomic controls, and vibration-reducing seats enhance operator comfort, reducing fatigue during long work hours. Additionally, advanced braking systems and clear visibility reduce accident risks on job sites.

Energy Efficiency and Fuel Savings

Fuel efficiency is another highlight of vibratory rollers. By delivering effective compaction in fewer passes, they consume less fuel, reducing operational costs and carbon emissions. Manufacturers are also integrating eco-friendly engines and hybrid technologies, further boosting their sustainability credentials.

Choosing the Right Vibratory Roller

Key Factors to Consider

Selecting the ideal vibratory roller depends on factors such as project scale, material type, and job site conditions. Drum size, frequency, and amplitude settings should align with the specific requirements of your project. Additionally, features like maneuverability and fuel efficiency can influence your decision.

Popular Models and Their Specifications

Manufacturers like Caterpillar, BOMAG, and Dynapac offer a range of vibratory rollers with varying specifications. For example, Caterpillar’s CB10 model boasts high-frequency vibration settings for asphalt compaction, while BOMAG’s BW120 series is tailored for smaller-scale projects. Understanding these differences helps match the roller to your needs.

Cost vs. Value Analysis

While vibratory rollers may have higher upfront costs than other compactors, their efficiency and durability deliver long-term value. By reducing labor hours, fuel consumption, and maintenance expenses, they often provide a better return on investment for large and small projects alike.

Maintenance and Longevity of Vibratory Rollers

Routine Maintenance Tips

Routine maintenance is essential to ensure your vibratory roller operates at peak performance. Regularly check and clean the drum, inspect the hydraulic system, and lubricate moving parts. Adhering to the manufacturer’s maintenance schedule minimizes downtime and extends the machine’s lifespan.

Common Issues and Troubleshooting

Common issues with vibratory rollers include drum vibration irregularities, hydraulic leaks, and engine overheating. Addressing these problems promptly through troubleshooting or professional servicing prevents further damage and keeps the equipment reliable.

Extending the Lifespan of Your Equipment

Proper storage, regular inspections, and timely repairs are key to extending the lifespan of your vibratory roller. Using genuine spare parts and avoiding overloading the machine ensures long-term durability and consistent performance.

Emerging Trends in Compaction Technology

Integration of Smart Technology in Vibratory Rollers

The construction industry is embracing smart technology, and vibratory rollers are no exception. Features like GPS tracking, automated controls, and real-time monitoring enhance precision and efficiency. These innovations help contractors meet project requirements with greater accuracy and reduced waste.

Sustainable Practices in Road Construction

Sustainability is driving innovation in compaction technology. Manufacturers are developing eco-friendly rollers that use biodegradable hydraulic fluids and fuel-efficient engines. These advancements align with global efforts to reduce the environmental impact of construction projects.

Future Innovations to Look Forward To

Future developments in vibratory rollers may include fully autonomous models, AI-powered diagnostics, and enhanced energy efficiency. These innovations promise to revolutionize the construction industry, making projects faster, safer, and more sustainable.

Case Studies: Vibratory Rollers in Action

Success Stories from Road Construction

Case studies demonstrate how vibratory rollers outperform other compactors in real-world applications. For instance, a highway project in India achieved a 30% reduction in construction time using vibratory rollers, thanks to their ability to compact materials efficiently in fewer passes.

Comparing Results with Other Compactors

In a comparative analysis, vibratory rollers consistently outperformed plate compactors and rammers in terms of compaction depth and uniformity. Their ability to handle large-scale projects with minimal operator effort makes them a superior choice.

Insights from Industry Experts

Industry professionals emphasize the importance of vibratory rollers for modern construction. Their versatility, efficiency, and adaptability make them an indispensable tool for achieving high-quality results across various applications.

Conclusion

Summary of Benefits of Vibratory Rollers

Vibratory rollers offer unmatched efficiency, versatility, and durability for compaction tasks. Their ability to deliver uniform results across various materials and applications makes them an invaluable asset for construction professionals.

Final Thoughts and Recommendations

When choosing compaction equipment, vibratory rollers stand out as the optimal choice for projects of all sizes. Their superior performance, cost-effectiveness, and adaptability ensure high-quality results, making them a worthwhile investment.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.