Road Roller Machine PME-R1500

When you are looking for a road roller machine, we can assist you in selecting the most suitable compactor roller for your business.

Road Roller Machine PME-R1500

The PME-R1500 Road Roller Machine is a robust and efficient compaction solution, designed to handle large-scale construction and roadwork projects with ease. Featuring dual rollers measuring 530 mm in diameter and 800 mm in width, it offers outstanding performance and reliability for a wide variety of compaction tasks, ensuring smooth and durable surfaces every time.

Powerful Performance

The PME-R1500 is powered by either a ChangChai 192FAE or ChangFa CF13 engine, providing consistent and powerful operation for demanding projects. Its hydraulic double-wheels drive ensures smooth and efficient movement, while the front-wheel hydraulic vibration system delivers a centrifugal force of 30 KN and a vibration frequency of 75 Hz. With a nominal amplitude of 0.5 mm, this road roller offers precise and effective compaction for asphalt, gravel, and soil, making it suitable for diverse materials and surfaces.

Versatile Application

The PME-R1500 is engineered for versatility, excelling in road construction, soil stabilization, and foundation preparation. Its hydraulic steering system provides a steering radius of 2100 mm, allowing excellent maneuverability in tight or confined spaces. The machine’s gradeability of 30° ensures reliable performance on slopes and uneven terrain, while the travel speed of 0-8 km/h enables efficient operation across large and small job sites. This flexibility makes it a preferred choice for contractors handling complex and varied projects.

Built to Last

Durability is a hallmark of the PME-R1500. Constructed with high-quality materials, this machine is built to endure rigorous use in demanding construction environments. Its hydraulic systems ensure smooth operation and reduce the need for frequent maintenance, minimizing downtime and maximizing productivity. Whether used for compacting subgrades, stabilizing soil, or laying foundations, the PME-R1500 is designed to deliver reliable and long-lasting performance.

Applications

- Road Construction and Maintenance

- Asphalt, Gravel, and Soil Compaction

- Foundation and Subgrade Preparation

- Soil Stabilization Projects

- Large-Scale Infrastructure Development

- Compaction on Slopes and Uneven Terrain (Gradeability: 30°)

- Tight and Open Workspaces

- Pathways, Driveways, and Landscaping

With its powerful engine, advanced hydraulic systems, and precise vibration control, the PME-R1500 Road Roller Machine is a reliable and efficient choice for contractors and professionals. Its robust design, user-friendly operation, and superior performance make it a valuable tool for achieving high-quality compaction results on any construction site.

Key Specifications

| Model | Road Roller Machine PME-R1500 |

|---|---|

| Engine | ChangChai 192FAE/ChangFa CF13 |

| Roller size [diameter x width] | 2xφ530x800 mm |

| Drive type | Hydraulic double wheels drive |

| Vibration type | Hydraulic front wheel vibrate |

| Steering mode | Hydraulic control |

| Steering radius | 2100 mm |

| Nominal amplitude | 0.5 mm |

| Vibration frequency | 75 Hz |

| Centrifugal force | 30 KN |

| Gradeability | 30° |

| Travel speed | 0-8 km/h |

| N.W./G.W. | 1380/1400 kg |

| Package size | 230x100x165 cm |

ADVANTAGE

Exquisite Workmanship

The hood of the road roller showcases excellent craftsmanship. The bright yellow paint is flawlessly applied, providing a smooth and vibrant finish.

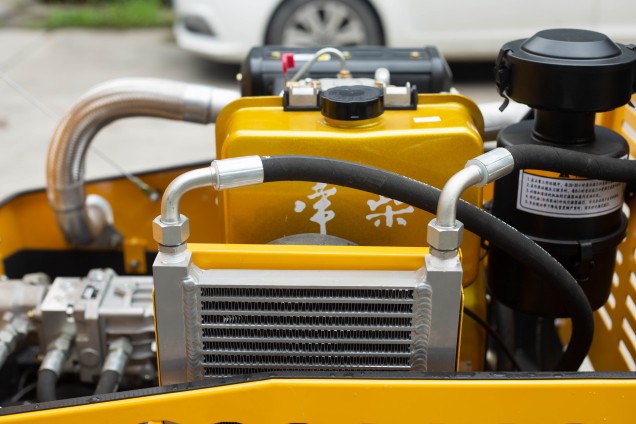

Efficient Engine Compartment Organization

The engine compartment is organized with components such as hoses, filters, and the engine block properly placed.This organized layout facilitates maintenance and ensures the smooth operation of the road roller's engine.

Large Compaction Drum

The roller features a large compaction drum at the front. This drum is responsible for compacting soil, asphalt, and other construction materials. The large size of the drum ensures a smooth and even compaction surface.

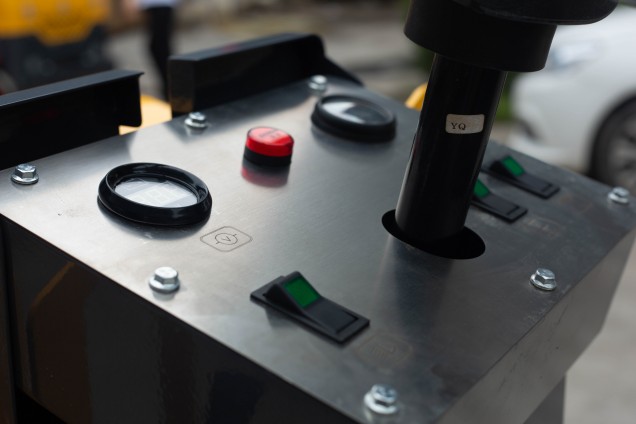

Intuitive Control Panel Layout

The control panel features a well - arranged layout with clearly marked buttons and gauges. This design allows for easy access and operation, reducing the likelihood of errors and improving the efficiency of the road roller's functions.

Comfortable Seat

The roller is equipped with a cushioned seat, providing comfort for the operator during extended use. It is flanked by handlebars, providing a secure and comfortable operating position for the operator, which enhances the overall usability of the road roller.

Drum with Scraper

The roller is equipped with a drum that has a built - in scraper. The scraper helps to remove any material that may stick to the drum during the compaction process, ensuring that the drum remains clean and effective. This feature is crucial for maintaining the quality of the compaction work.

QUESTIONS & ANSWERS

A road roller is a heavy machine used for compaction, ensuring stability and longevity in infrastructure projects.

To compact surfaces like soil, asphalt, or concrete, ensuring stability and durability.

Vibratory rollers use oscillations for compaction, while static rollers rely solely on weight.

Yes, they are often utilized in land reclamation and environmental restoration to compact soil layers.

Operators should undergo proper training, wear protective gear, and adhere to operational guidelines.

Yes, smaller models are available for residential and minor construction projects.

Regular checks of the engine, hydraulic system, and drum condition are essential.

Many modern road rollers feature fuel-efficient engines and emissions control technologies.

They are more eco-friendly and energy-efficient, but their suitability depends on the project’s requirements.

Other Similar Products

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Road Roller Machine

Road roller machines are heavy-duty vehicles designed to compact surfaces, such as soil, gravel, asphalt, or concrete. They are integral to construction and paving projects, ensuring a strong and even foundation.

The Ultimate Guide to Road Roller Machines: Types, Uses, and Innovations

Introduction

Road roller machines are the unsung heroes of modern infrastructure. From highways to residential streets, these robust machines ensure surfaces are compact and stable, supporting the weight of vehicles for years to come. But what exactly makes road rollers essential, and how have they revolutionized construction? This guide unpacks everything you need to know about these powerful machines.

History of Road Roller Machines

The road roller machine’s journey began in the late 19th century, initially powered by steam engines. Over the years, they evolved to include internal combustion engines and, more recently, hybrid and electric models. These advancements have made road rollers more efficient and environmentally friendly.

Components of a Road Roller Machine

1. Engine

The powerhouse of the machine, typically diesel-powered, provides the energy needed for the roller to function efficiently.

2. Drum

The large cylindrical drum is the defining feature of a road roller. It compresses soil, asphalt, or other materials.

3. Hydraulic Systems

Hydraulics ensure smooth operations, from drum movement to steering.

4. Frame

A sturdy frame supports all components, ensuring durability under heavy use.

Types of Road Roller Machines

1. Static Rollers

These rely on the weight of the machine to compress materials, making them ideal for finishing layers.

2. Vibratory Rollers

Equipped with vibrating drums, these rollers compact materials more efficiently, especially for granular surfaces.

3. Pneumatic Rollers

These use multiple rubber tires to compact materials, suitable for finishing asphalt layers.

4. Combination Rollers

As the name suggests, these machines combine features of static and vibratory rollers, offering versatility.

Applications of Road Roller Machines

1. Road Construction

From highways to driveways, road rollers prepare surfaces for long-term durability.

2. Landscaping

Road rollers are instrumental in leveling and compacting soil for landscaping projects.

3. Industrial Applications

Used in warehouses and industrial complexes, road rollers ensure stable foundations.

Working Mechanism

The principle behind road rollers is simple: weight and vibration compress the material, eliminating air gaps and increasing density. Modern rollers use advanced technology to achieve uniform compaction with minimal passes.

Advantages of Using Road Roller Machines

Efficiency: Speeds up construction timelines.

Cost-Effectiveness: Reduces the need for extensive labor.

Durability: Enhances the lifespan of roads and foundations.

Challenges in Operating Road Rollers

Uneven compaction.

Engine malfunctions.

Operator fatigue.

However, regular training and maintenance can mitigate these issues.

Safety Measures for Operators

Always wear protective gear.

Follow the manufacturer’s guidelines.

Regularly inspect the machine for faults.

Environmental Considerations

Modern road rollers are designed with sustainability in mind. Hybrid models and advanced emissions control technologies reduce their environmental footprint.

Innovations in Road Roller Machines

Autonomous road rollers guided by GPS.

Noise-reducing technology.

Energy-efficient electric models.

Maintenance and Care

Regularly check oil levels and hydraulics.

Clean the drum to prevent material buildup.

Address minor issues promptly to avoid costly repairs.

Comparing Top Brands

| Brand | Key Features |

| Dimec | Durable and fuel-efficient models. |

| Volvo | Advanced safety features and eco-friendly designs. |

| Dynapac | Known for innovative technology in vibratory rollers. |

| Wirtgen Group | Specializes in autonomous and high-tech solutions. |

Factors to Consider Before Purchase

Drum Width: Determines the area covered per pass.

Engine Power: Impacts performance and efficiency.

Fuel Efficiency: Reduces operational costs.

Future Trends in Road Roller Machines

The integration of AI and IoT is set to redefine the industry. Smart road rollers will provide real-time data, improving efficiency and reducing human error.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.