Ride On Vibro Roller PME-R6000

When you are looking for a vibro roller compactor, we can assist you in selecting the most suitable compactor roller for your business.

Ride On Vibro Roller PME-R6000

The PME-R6000 Ride On Vibro Roller is a highly efficient and robust machine designed for large-scale compaction projects, including road construction, asphalt paving, and foundation preparation. With roller widths of 1350 mm and 1480 mm, this roller is perfect for achieving deep, uniform compaction across expansive job sites, ensuring smooth and durable surfaces that meet high-quality standards.

Powerful Performance

Powered by the reliable ChangChai ZN490B engine with 39KW of power, the PME-R6000 delivers exceptional compaction performance, making it an ideal choice for demanding tasks. Its hydraulic vibration system generates a centrifugal force of 75 KN, providing powerful, deep compaction for various materials such as asphalt, gravel, and soil. Operating at a vibration frequency of 60 Hz, the PME-R6000 ensures consistent results, with a nominal amplitude that guarantees thorough compaction for stable and long-lasting surfaces.

Versatile Application

The PME-R6000 excels in a wide range of applications, including road construction, soil stabilization, and subgrade preparation. Its versatile hydraulic vibration system ensures smooth and efficient compaction even on large or uneven surfaces. The machine features a wheelbase of 2350 mm and a steering radius of 5300 mm, providing exceptional maneuverability and stability across large and confined work areas. With a travel speed of 0-8 km/h, it allows operators to cover substantial ground quickly without compromising compaction quality.

Built to Last

Constructed with high-quality materials, the PME-R6000 is built to withstand the rigors of continuous, heavy-duty use. The hydraulic systems are designed for durability and performance, and the machine’s 80L hydraulic oil capacity ensures long-lasting and smooth operation, minimizing downtime and enhancing productivity. Whether for large-scale infrastructure projects or extensive roadwork, the PME-R6000 is engineered to handle demanding jobs with ease and reliability.

Applications

- Road Construction and Maintenance

- Asphalt, Gravel, and Soil Compaction

- Large-Scale Infrastructure Projects

- Foundation and Subgrade Preparation

- Soil Stabilization Projects

- High-Efficiency Compaction for Large Job Sites

- Compaction in Confined or Tight Spaces

- Driveways, Pathways, and Landscaping

With its powerful engine, advanced hydraulic systems, and high centrifugal force, the PME-R6000 Ride On Vibro Roller is the perfect choice for contractors seeking a reliable and efficient compaction solution. Its durable construction, ease of use, and exceptional performance make it an essential tool for any large-scale compaction task, ensuring top-quality results and high productivity across every project.

Key Specifications

| Model | Ride On Vibro Roller PME-R6000 |

|---|---|

| Engine | ChangChai ZN490B/39KW |

| Roller width | 1350/1480 mm |

| Wheel base | 2350 mm |

| Vibration type | Hydraulic vibration |

| Steering radius | 5300 mm |

| Vibration frequency | 60Hz |

| Centrifugal force | 75 KN |

| Hydraulic oil capacity | 80 L |

| Travel speed | 0-8 km/h |

| N.W. | 5500 kg |

| Overall size | 450x161x260 cm |

ADVANTAGE

Exquisite Workmanship

The hood of the road roller showcases excellent craftsmanship. The bright yellow paint is flawlessly applied, providing a smooth and vibrant finish.

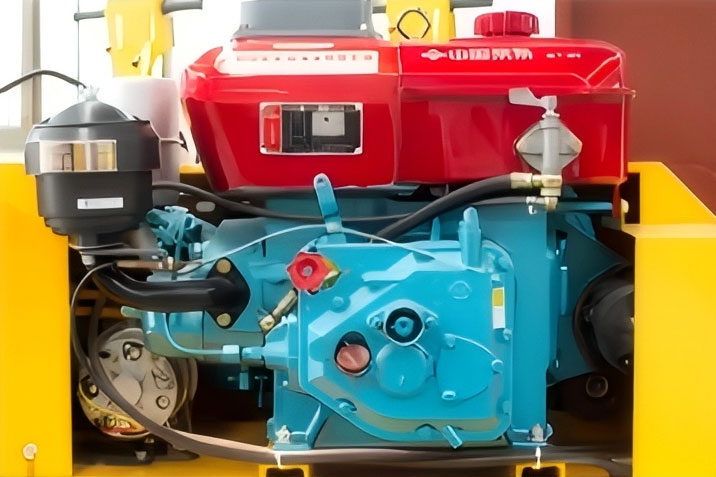

Changchai Engine Quality

The Changchai diesel engine complies with national three - emission standards. It is a reliable brand, offering strong power and easy starting.

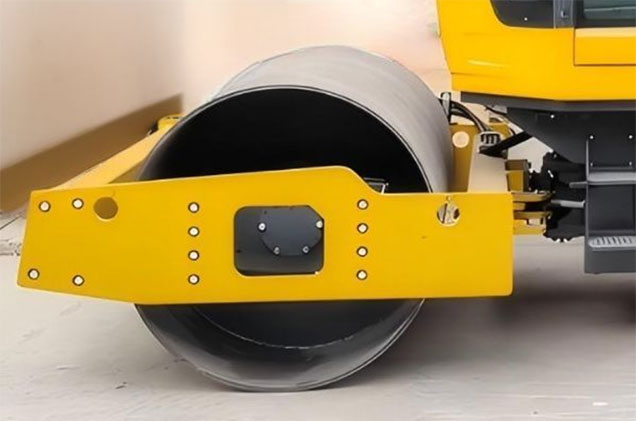

Thickened Steel Wheel

The thickened steel wheel provides the roller with robust compaction capabilities. It can perform static or vibration compaction independently, meeting diverse engineering requirements.

Intuitive Operation Functions

The hydraulic system is composed of internationally well - known cycloid hydraulic motors and variable plunger pumps. It offers stability, with features like two - wheel drive, hydraulic power steering, and efficient front - wheel vibration.

Comfortable Seat

The optional cockpit, along with luxurious operating handles and seats, is designed to provide the operator with a comfortable operating experience. This ergonomic design ensures that the operator can work with ease and minimal fatigue during long - term use.

Hydraulic System

The internationally renowned brand cycloid hydraulic motor and variable plunger pump constitute a stable hydraulic system, front and rear two-wheel drive walking, hydraulic power steering, front wheel hydraulic vibration, stable vibration and fast vibration.

QUESTIONS & ANSWERS

A Ride On Vibro Roller uses vibration to assist in the compaction of materials, while a static roller relies solely on its weight. Vibro rollers are generally more efficient, offering deeper and more uniform compaction, especially in large-scale projects.

When choosing a Ride On Vibro Roller, consider the size of the project, the material being compacted, and the terrain. Larger projects may require a roller with higher horsepower, while smaller tasks can be handled with a more compact model.

A single drum roller has one vibrating drum, while a double drum roller has vibrating drums on both the front and rear for better balance and compaction.

Yes, Ride On Vibro Rollers can be used on soft soil, but they are most effective on granular materials like gravel and sand. For softer soils, a lower vibration amplitude might be needed to avoid damaging the material.

With proper maintenance, a Ride On Vibro Roller can last anywhere from 8 to 12 years. Regular upkeep and timely repairs will significantly extend its operational life.

Routine maintenance tasks include checking oil and hydraulic fluid levels, inspecting the vibration system, and ensuring that all moving parts are lubricated. Regularly cleaning the roller and checking for any signs of wear and tear will also help extend its lifespan.

Yes, Ride On Vibro Rollers are generally safe to operate, especially when proper safety protocols are followed. This includes wearing appropriate personal protective equipment (PPE), ensuring the machine is in good working condition, and adhering to manufacturer safety guidelines.

Prices vary based on brand, features, and specifications, with higher-end models costing more. Renting might be a more economical option for short-term use.

Other Similar Products

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Ride On Vibro Roller

Construction projects require powerful, reliable equipment, and one of the most essential machines for achieving optimal compaction is the Ride On Vibro Roller. This heavy-duty roller is crucial in road construction, pavement work, and other large-scale projects where a smooth, stable surface is necessary. Whether you’re working on highways, industrial sites, or municipal projects, a ride-on vibro roller ensures that the ground is compressed efficiently to avoid future issues.

Introduction to Ride On Vibro Roller

A Ride On Vibro Roller is an essential piece of machinery used in the construction and roadwork industry, designed to compact various surfaces, such as asphalt and soil. The primary function of this roller is to apply vibration and pressure to the ground to achieve a smooth, even surface with the desired density. These machines are often employed in large-scale projects like road construction, airport runways, and industrial site preparation. This article explores the features, benefits, types, and maintenance of Ride On Vibro Rollers, along with providing insight into their application in modern construction and landscaping projects.

What is a Ride On Vibro Roller?

A Ride On Vibro Roller is a self-propelled compaction machine equipped with one or two vibrating drums. The vibrations generated by the drums help to compact the material beneath, increasing its density and stability. The “ride-on” aspect means that the operator sits comfortably on the machine, giving them better control and efficiency when navigating through job sites.

These machines come in different configurations, including single drum, tandem, and combination rollers. The vibration mechanism is essential for providing the right amount of compaction force to achieve optimal results, making them an indispensable tool for modern construction.

The Purpose and Benefits of Ride On Vibro Rollers

The primary purpose of a Ride On Vibro Roller is to improve the compaction of granular materials such as soil, gravel, sand, and asphalt. The benefits are manifold:

- Enhanced Compaction: The vibration technology ensures deep compaction, which is difficult to achieve using static rollers alone.

- Increased Efficiency: Ride On Vibro Rollers are faster than manual compaction methods, leading to time savings and higher productivity.

- Operator Comfort: With the operator seated on the machine, they experience less physical strain, leading to improved focus and longer working hours.

- Surface Quality: The vibration mechanism smoothens the surface, ensuring a high-quality finish that is essential for long-lasting roads and pavements.

Understanding the Mechanics of Ride On Vibro Rollers

How a Ride On Vibro Roller Works

A Ride On Vibro Roller operates by utilizing the rotating drums that vibrate at a specific frequency. These vibrations are applied to the surface of the material being compacted. The force from the roller combined with the vibration helps to break down air pockets within the material, making it denser and more stable. This process is essential in ensuring that the surface can withstand the pressure and wear it will experience over time.

The mechanism typically involves the use of a hydraulic system that controls the vibration amplitude, allowing operators to adjust it based on the type of material being compacted. Additionally, the drums can either be smooth or equipped with a pattern depending on the application.

Key Components of a Ride On Vibro Roller

- Vibrating Drums: These are the main compaction components, which vibrate and apply pressure to the surface.

- Engine: Most Ride On Vibro Rollers are powered by a diesel engine, offering sufficient power to drive the vibration mechanism and propulsion system.

- Hydraulic System: This system controls the vibration intensity and movement of the machine.

- Operator Cabin: The operator sits in a cushioned seat, with controls to adjust the speed, vibration level, and steering, ensuring a smooth operation.

Types of Ride On Vibro Rollers

Single Drum Rollers: Overview and Applications

Single drum rollers are equipped with a single vibrating drum in the front, while the rear is typically smooth. These are ideal for compacting granular materials like sand, gravel, and soil. They are most commonly used in smaller construction projects where the surface is not too thick, such as driveways and parking lots. The single drum roller can maneuver easily around tight corners, making it a versatile tool for various tasks.

Tandem Rollers: Features and Uses

Tandem rollers have two vibrating drums—one at the front and one at the back—allowing for more uniform compaction. This type is typically used for road construction and asphalt compaction, where a higher level of smoothness and uniform density is required. The two drums work together to apply consistent pressure, which helps create a smooth, even surface for high-traffic areas like highways.

Combination Rollers: Pros and Cons

Combination rollers feature both a smooth drum in the front and a pneumatic tire roller in the rear. This design combines the benefits of both the vibrating roller and tire roller, providing deeper compaction and better surface finishing. They are particularly useful for tasks that require a high level of precision, such as compacting base layers for road construction.

Applications of Ride On Vibro Rollers

Construction Sites: Impact and Efficiency

On construction sites, Ride On Vibro Rollers are used for compacting the subbase and base layers of roads, buildings, and other infrastructure projects. The ability to apply vibration ensures that the compaction is deeper and more uniform than what can be achieved using manual methods. This leads to a stronger foundation for construction, reducing the likelihood of future settling or cracking.

Road and Pavement Construction: Why Vibro Rollers are Essential

In road and pavement construction, the quality of the surface is paramount. Ride On Vibro Rollers play a crucial role in ensuring that asphalt or concrete is compacted properly. Without proper compaction, roads can become uneven, prone to cracking, and have a shorter lifespan. Vibro rollers, with their ability to adjust vibration intensity, help achieve the required density and smoothness.

Landscaping and Agricultural Uses of Ride On Vibro Rollers

While primarily associated with construction, Ride On Vibro Rollers also have applications in landscaping and agricultural projects. In landscaping, they are used for compacting large areas of soil to prepare for new grass or plantings. In agriculture, these rollers help to prepare the land for planting, ensuring that the soil is stable enough to support crops.

Features to Look for in Ride On Vibro Rollers

Engine Power and Fuel Efficiency

When choosing a Ride On Vibro Roller, it’s essential to consider the engine power. A higher horsepower engine allows for better performance, especially in tough conditions. Additionally, fuel efficiency is a key factor, as these machines are often used for long hours in remote locations. Modern machines are designed to balance power with fuel efficiency, reducing operational costs.

Vibration Control and Amplitude Adjustment

The ability to control the vibration intensity and amplitude is another important feature. Different surfaces require different compaction methods, so having a machine that allows for fine-tuned adjustments ensures optimal results. Whether working with asphalt, gravel, or soil, being able to adjust the vibration helps in achieving uniform compaction and avoiding damage to the material.

Safety Features: What to Consider

Safety is critical when operating heavy machinery like a Ride On Vibro Roller. Look for machines equipped with features like seat belts, rollover protection systems, and emergency stop buttons. Additionally, clear visibility for the operator and advanced braking systems are crucial for safe operation in busy construction environments.

Durability and Maintenance Considerations

A Ride On Vibro Roller is a significant investment, so it’s important to consider durability and ease of maintenance. Machines made from high-quality materials and those that offer easy access to components for routine maintenance tend to last longer. Regular maintenance, such as checking the vibration system and engine performance, will ensure the machine operates efficiently over its lifespan.

Ride On Vibro Rollers vs. Static Rollers

Differences in Operation and Efficiency

One of the key distinctions between Ride On Vibro Rollers and static rollers lies in the compaction mechanism. Static rollers rely solely on the weight of the machine to compact the material, while Ride On Vibro Rollers use vibration in addition to their weight to achieve better compaction. The vibrating action helps break down air pockets and forces particles closer together, which significantly improves the compaction density. This leads to a stronger, more stable foundation, which is crucial for projects that require high levels of precision.

In terms of efficiency, Ride On Vibro Rollers outperform static rollers, especially in larger projects. The vibration system accelerates the compaction process, reducing the time needed to achieve the desired result. While static rollers might be sufficient for light-duty applications, Ride On Vibro Rollers are preferred in large-scale construction projects due to their superior performance and faster work rates.

Cost Considerations: Which One is Right for Your Project?

While Ride On Vibro Rollers are typically more expensive to purchase or rent compared to static rollers, they can be more cost-effective in the long run. The higher initial cost is offset by the increased speed and efficiency of the compaction process. Additionally, the superior compaction results lead to fewer issues during later stages of construction, reducing the likelihood of costly repairs or delays.

Static rollers, on the other hand, may be a more economical option for smaller projects where deep compaction is not as critical. For larger-scale projects, however, the time saved by using a Ride On Vibro Roller can justify the additional investment.

Selecting the Right Ride On Vibro Roller for Your Project

Key Factors to Consider When Choosing a Vibro Roller

When selecting a Ride On Vibro Roller, several factors need to be considered to ensure that the right machine is chosen for the job:

Project Size and Scope: The larger the project, the more powerful the machine you’ll need. For expansive roads or large construction sites, a heavy-duty roller with a higher engine power is required.

Soil and Material Type: Different materials require different compaction levels. Make sure the roller’s vibration control is adjustable, allowing you to adapt to the material being compacted, whether it’s loose soil, gravel, or asphalt.

Drum Configuration: Depending on the nature of the project, you may need a single drum roller, a tandem roller, or a combination roller. For projects involving both compaction and smooth finishes, a combination roller might be more suitable.

Terrain and Accessibility: Consider the terrain of the job site. Some rollers are better suited for uneven or rough ground, while others are more effective on flat surfaces. Choose a model that matches your project’s unique challenges.

Budget vs. Quality: Striking the Right Balance

Finding the right balance between budget and quality is essential. A Ride On Vibro Roller is a long-term investment, so it’s important not to compromise too much on quality to save costs. Opting for a machine that may be slightly more expensive but offers better durability, fuel efficiency, and ease of maintenance can reduce operational costs over time. Conversely, selecting a cheaper, lower-quality model might save money upfront, but may lead to higher repair costs and shorter machine life.

Size and Weight Considerations for Different Types of Projects

The size and weight of a Ride On Vibro Roller will directly affect its ability to compact different materials. Heavier rollers are generally more effective on larger projects that involve deep compaction, such as road construction or airport runways. Lighter rollers are better suited for smaller, more delicate tasks, like driveway compaction or parking lot preparation. The weight also affects maneuverability; for confined areas or complex sites, a lighter, more compact roller may be more appropriate.

Benefits of Using a Ride On Vibro Roller

Time and Labor Efficiency: Why Vibro Rollers are a Game Changer

One of the most significant advantages of using a Ride On Vibro Roller is the substantial time savings. Traditional methods of compacting materials, such as manual compaction or static rollers, can be labor-intensive and time-consuming. Vibro rollers, on the other hand, reduce the amount of manual labor needed, allowing for faster completion of tasks.

The vibrating action ensures deeper and more uniform compaction with fewer passes, meaning that operators can get more done in less time. This increased efficiency not only speeds up project timelines but also reduces labor costs, making the overall operation more cost-effective.

Better Compaction and Surface Quality

Ride On Vibro Rollers provide superior compaction compared to static or manual methods. The vibration action helps to remove air pockets in the material, leading to a denser, more stable surface. This is especially important in road construction, where uneven compaction can result in cracking and other issues over time.

The smooth, uniform compaction achieved by vibro rollers also results in a higher-quality surface. Whether you’re building a road, a parking lot, or a foundation, a well-compacted surface provides better durability and longevity, reducing the need for repairs down the line.

Reduced Fatigue for Operators

Operating heavy machinery for long periods can be exhausting, but the Ride On Vibro Roller offers a much more comfortable working experience than other types of rollers. With a seated design, operators can work for longer stretches without the physical strain that comes with walking or standing.

This increased comfort allows operators to remain focused and efficient throughout the workday. In turn, this can contribute to better safety outcomes and higher productivity on the job site.

Maintenance and Care for Ride On Vibro Rollers

Routine Maintenance Tips to Keep Your Vibro Roller in Top Condition

To ensure that your Ride On Vibro Roller remains in good working order, regular maintenance is crucial. Key maintenance tasks include:

- Checking Oil Levels: Regularly check the oil levels and change the oil as per the manufacturer’s recommendation.

- Inspecting the Vibrating Mechanism: Ensure that the vibration system is functioning properly and that there are no blockages in the hydraulic system.

- Tire and Drum Inspection: Check for wear and tear on the tires and drums. If the drums become damaged or worn, they will need to be replaced to maintain optimal compaction performance.

Performing these maintenance tasks helps extend the lifespan of the roller and ensures that it remains efficient throughout its service life.

Troubleshooting Common Issues and How to Fix Them

Common issues with Ride On Vibro Rollers include vibration irregularities, engine trouble, and hydraulic system failures. To troubleshoot these problems:

- Vibration Irregularities: Ensure that the vibration frequency is correctly set for the material being compacted. Check the hydraulic system for leaks or blockages.

- Engine Issues: Inspect the fuel filter and replace it if necessary. Regularly check air filters and spark plugs to avoid engine misfires.

- Hydraulic System Failures: Inspect hydraulic hoses for leaks and replace them if needed.

By addressing these common issues promptly, you can minimize downtime and keep the roller in top condition.

Best Practices for Storing and Transporting Ride On Vibro Rollers

Proper Storage Techniques for Longevity

When not in use, it’s essential to store Ride On Vibro Rollers in a safe, dry location to prevent rust and damage from weather elements. A covered area, such as a garage or shed, is ideal for storage. Additionally, ensure that the machine is parked on a level surface to avoid strain on the hydraulic system.

Before storing, perform basic maintenance, such as cleaning the machine and checking fluid levels. If the roller will be stored for an extended period, it’s also advisable to remove the battery to prevent corrosion and ensure that the machine is ready to operate when needed.

Transporting Your Ride On Vibro Roller Safely

Transporting a Ride On Vibro Roller requires careful consideration to avoid damage to the machine or any surrounding property. Follow these key guidelines:

- Use a Flatbed Trailer: For safe transport, always use a flatbed trailer with sufficient weight capacity. Ensure the machine is securely fastened to avoid any shifting during transit.

- Proper Loading: When loading the roller onto the trailer, make sure the roller’s wheels or tracks are aligned with the ramps. Drive the machine up slowly, ensuring that the ramp is stable and free of obstacles.

- Check Transportation Regulations: If transporting the machine over long distances or across state lines, be sure to check any regulations regarding transportation size, weight, and permits.

By adhering to these best practices for storage and transport, you can prevent unnecessary wear and tear and extend the service life of your Ride On Vibro Roller.

Ride On Vibro Roller Manufacturers

Leading Manufacturers in the Industry and Their Offerings

Several well-established companies manufacture Ride On Vibro Rollers, each offering unique models with varying features to suit different needs. Some of the top manufacturers include:

Caterpillar (CAT): Known for producing high-quality construction machinery, CAT offers a wide range of Ride On Vibro Rollers with powerful engines and efficient compaction systems. Their models are widely used in large-scale road construction projects.

Bomag: A global leader in compaction equipment, Bomag is known for their advanced vibration technology and durable machines. Their Ride On Vibro Rollers are ideal for heavy-duty tasks and provide excellent fuel efficiency.

Volvo: Known for their robust and reliable construction machinery, Volvo offers Ride On Vibro Rollers designed for both smooth and tough terrains. They prioritize operator comfort and safety, making them popular among contractors.

Sakai: Sakai produces versatile Vibro Rollers with exceptional performance in compaction across a variety of materials. Their models are designed for high efficiency and come with advanced features for vibration control.

Comparing Features and Costs Among Top Brands

While comparing different models and manufacturers, several factors should be considered:

Engine Power and Fuel Efficiency: Depending on the project size, it may be important to choose a roller with a powerful engine. Larger rollers typically offer higher engine power, which is required for tougher jobs. Fuel efficiency is another essential consideration, as machines that consume less fuel lower the operational costs.

Ease of Use and Comfort: Look for models with user-friendly controls, comfortable seating, and effective vibration dampening systems. These features enhance productivity and reduce operator fatigue.

Maintenance and Durability: Some manufacturers offer models with easier access to parts, which can lower maintenance time and costs. Models with longer service intervals and durable components are often a better investment in the long run.

Future Trends in Ride On Vibro Rollers

Technological Innovations in Vibro Roller Design

As technology advances, so does the design of Ride On Vibro Rollers. The introduction of smart technology is one of the biggest trends in the industry. Many modern rollers come equipped with telematics, allowing operators and fleet managers to remotely monitor the machine’s performance. This technology provides real-time data on fuel consumption, compaction progress, and maintenance needs, helping to increase operational efficiency and reduce downtime.

Another innovation is the development of electrically powered Vibro Rollers, which significantly reduce emissions and fuel consumption. As the construction industry moves toward more sustainable practices, electric and hybrid models are becoming increasingly popular.

The Role of Eco-Friendly and Electric Ride On Vibro Rollers in Sustainable Construction Practices

Sustainability has become a major focus in the construction industry, and eco-friendly Ride On Vibro Rollers are playing a crucial role in this shift. These machines not only help reduce environmental impact by decreasing fuel consumption, but they also lower noise pollution and emissions. Electric Ride On Vibro Rollers, in particular, offer a cleaner alternative to their diesel-powered counterparts, making them an excellent choice for projects in urban areas or environmentally sensitive zones.

As governments and organizations continue to push for more eco-friendly construction practices, the demand for sustainable equipment like electric Vibro Rollers is expected to grow. This trend aligns with broader industry efforts to reduce carbon footprints and achieve net-zero emissions targets.

Conclusion

Ride On Vibro Rollers are indispensable machines in the construction and roadwork industries, providing efficient compaction, improved surface quality, and operator comfort. Whether you’re building roads, preparing construction sites, or compacting soil for landscaping, the versatility and power of these machines make them a key part of modern construction practices.

With advancements in technology, such as the integration of telematics and the development of eco-friendly electric models, the future of Ride On Vibro Rollers looks promising. By choosing the right machine for your specific needs, maintaining it properly, and leveraging innovations in the field, you can enhance the efficiency and quality of your projects for years to come.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.