Compactor Roller PME-R900

When you are looking for a compactor roller, we can assist you in selecting the most suitable compactor roller for your business.

Compactor Roller PME-R900

The PME-R900 Compactor Roller is a robust and versatile machine designed to meet the needs of professional contractors and construction teams tackling medium to large-scale compaction tasks. Featuring dual rollers with dimensions of 530 mm in diameter and 700 mm in width, this roller delivers reliable performance, efficient operation, and precise control, making it ideal for road construction, foundation preparation, and infrastructure projects.

Powerful Performance

Equipped with a ChangFa CF178FE or ChangChai R180 water-cooled engine, the PME-R900 provides consistent power and durability for demanding compaction tasks. The water-cooled, 4-stroke engine ensures reliable performance even in extended operations. With a centrifugal force of 20 KN and a vibration frequency of 70 Hz, this compactor roller is engineered to handle asphalt, gravel, and soil compaction efficiently. The front-wheel vibration, controlled by an electromagnetic system, ensures thorough and uniform compaction with a nominal amplitude of 0.5 mm.

Versatile Application

The PME-R900 is designed for a wide range of applications, from road repair and foundation work to large-scale construction projects. Its hydraulic drive system with stepless speed control allows for smooth and precise adjustments, while the rear-wheel steering provides excellent maneuverability with a steering radius of 1800 mm. With a gradeability of 30°, the PME-R900 performs exceptionally well on slopes and uneven terrain. Its travel speed range of 0-6 km/h ensures efficiency and control in both confined and open working environments.

Built to Last

Constructed for durability and long-term performance, the PME-R900 is made from high-quality materials to endure the challenges of frequent and heavy use. Its advanced hydraulic system ensures seamless operation, reducing maintenance needs and downtime. The robust build and precise vibration control make it a dependable choice for professionals working on demanding projects. Whether compacting subgrades or preparing foundations, the PME-R900 delivers exceptional results with every pass.

Applications

- Road Construction and Repair

- Asphalt, Gravel, and Soil Compaction

- Foundation and Subgrade Preparation

- Structural Work and Soil Stabilization

- Large-Scale Infrastructure Projects

- Pathways, Driveways, and Landscaping

- Compaction on Sloped Terrain (Gradeability: 30°)

- Tight and Open Space Projects

With its advanced features, powerful engine, and user-friendly design, the PME-R900 Compactor Roller is a reliable solution for high-quality compaction. Its precise steering, robust vibration control, and durable construction make it an essential tool for contractors aiming for efficiency and excellence in their projects.

Key Specifications

| Model | Compactor Roller PME-R900 |

|---|---|

| Engine | ChangFa CF178FE/ ChangChai R180 water cooled |

| Roller size [diameter x width] | 2xφ530x700 mm |

| Drive type | Hydraulic drive, Stepless speed change |

| Vibration type | Electromagnetic control; front wheel vibration |

| Steering mode | Rear wheel steer |

| Steering radius | 1800 mm |

| Nominal amplitude | 0.5 mm |

| Vibration frequency | 70 Hz |

| Centrifugal force | 20 KN |

| Gradeability | 30° |

| Travel speed | 0-6 km/h |

| N.W./G.W. | 750/780 kg |

| Package size | 190x85x130 cm |

ADVANTAGE

Ergonomic Design

The roller features an ergonomic design with a well - positioned handlebar. This design ensures operator comfort and ease of control, allowing for precise maneuvering.

Diesel - Powered Engine

It is equipped with a diesel - powered engine. This type of engine provides sufficient power for the roller to compact various materials effectively.

Large Compaction Drum

The roller features a large compaction drum at the front. This drum is responsible for compacting soil, asphalt, and other construction materials. The large size of the drum ensures a smooth and even compaction surface.

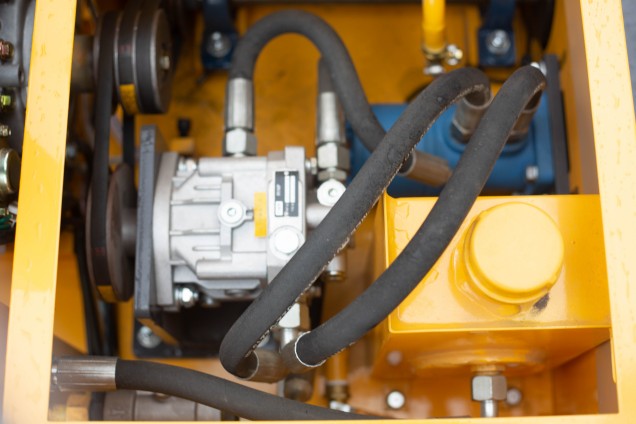

Reasonable Layout and Neat Wiring

The equipment presents a reasonable layout with orderly arranged components, optimizing space and easing maintenance. The wiring is neat, with cables grouped and routed well, reducing interference and tangling risks. This layout and wiring enhance system performance and reliability.

Comfortable Seat

The roller is equipped with a cushioned seat, providing comfort for the operator during extended use. This feature reduces fatigue and enhances productivity.

Drum with Scraper

The roller is equipped with a drum that has a built - in scraper. The scraper helps to remove any material that may stick to the drum during the compaction process, ensuring that the drum remains clean and effective. This feature is crucial for maintaining the quality of the compaction work.

QUESTIONS & ANSWERS

The most common types include smooth drum rollers, padfoot rollers, and tandem rollers.

Smooth drum rollers are ideal for flat surfaces, while padfoot rollers are designed for cohesive soils like clay.

Yes, but they are most effective on granular and cohesive soils.

Vibratory rollers are more effective for dense compaction, especially on granular materials.

Yes, pneumatic rollers work well for asphalt compaction.

Regular maintenance involves checking the drum, tires, and hydraulic system, as well as keeping the machine clean.

With proper care, a compactor roller can last 10-15 years or longer.

Ensure proper training, wear safety gear, and adhere to the manufacturer’s guidelines.

Evaluate your project’s requirements, soil type, and budget before selecting.

Other Similar Products

Concrete Saw PME-Q350

Road Saw PME-Q300

Ride On Vibro Roller PME-R6000

Road Roller Compactor PME-R3500

Construction Road Roller PME-R3000

Double Drum Road Roller PME-R2500

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Compactor Roller

Compactor rollers play an essential role in the construction and roadwork industries. From paving roads to preparing foundations, these machines ensure a stable and durable base by compressing soil, asphalt, or other materials. With several types available, choosing the right compactor roller depends on the specific requirements of your project.

What Are the Advantages of Mini Road Rollers?

Mini road rollers are compact, versatile, and highly efficient machines that have become a staple in modern construction and landscaping. These machines offer a range of advantages, especially in urban environments where space is limited and precision is key. In this article, we will explore what makes mini road rollers so beneficial, their applications, and how they stand out from their larger counterparts.

What Makes Mini Road Rollers Unique?

Mini road rollers, as the name suggests, are smaller versions of traditional road rollers. Despite their compact size, they pack a punch when it comes to performance. Here’s what makes them stand out:

Size and Maneuverability

One of the primary advantages of mini road rollers is their size. These machines are designed to fit into tight spaces, making them ideal for small-scale projects, urban roads, or residential driveways. Their compact design allows operators to maneuver easily around obstacles such as parked vehicles or narrow alleys. Unlike larger rollers, mini road rollers can operate in confined areas, making them a preferred choice for projects with limited access.

Engine Power and Efficiency

Mini road rollers are equipped with engines that, while smaller than those in standard rollers, still deliver impressive compaction power. The engines are designed to maximize fuel efficiency, providing long-lasting performance with less frequent refueling. Many mini road rollers come with modern hydraulic systems that ensure smooth operation and consistent performance throughout the day.

Versatility for Various Projects

Another remarkable feature of mini road rollers is their versatility. They can be used for a variety of construction and landscaping tasks, from compacting soil and asphalt to working on paving projects. Whether you’re paving a small pathway, constructing a driveway, or working on a larger road construction project, these machines can be adapted to different surfaces and conditions.

Advantages of Using Mini Road Rollers in Construction

When it comes to construction and landscaping projects, mini road rollers offer several key benefits that make them a valuable tool in any fleet.

Compact Design for Small Spaces

Mini road rollers are perfect for working in areas where larger machines would struggle. Their small footprint allows them to navigate through narrow spaces and confined areas with ease. Whether you’re working in an urban environment with narrow streets or need to access tight corners, mini road rollers are designed to fit in places where other machines simply can’t.

Enhanced Precision in Worksites

The precision with which mini road rollers can compact surfaces is another significant advantage. Due to their size and maneuverability, operators can achieve greater accuracy in the compaction process. This is especially important when working on intricate projects like parking lots, driveways, and pathways where uniform compaction is essential.

Cost-Effectiveness for Small Projects

Mini road rollers are more affordable compared to their larger counterparts. Their lower purchase price and reduced operating costs (fuel and maintenance) make them an excellent choice for small-scale projects. Moreover, since they are easier to transport and require less space to store, they can save you money on logistics and storage costs.

Cost-Effectiveness and Budget-Friendly Performance

Mini road rollers are not only cheaper to buy, but they also help businesses save money in the long term. Here’s how:

Lower Initial Investment

For small businesses or contractors who need a reliable compaction machine without the hefty price tag, mini road rollers are an excellent option. Their initial investment cost is significantly lower than that of full-sized road rollers, making them a viable choice for projects with tight budgets.

Reduced Maintenance Costs

Due to their compact size and simple design, mini road rollers tend to have lower maintenance costs. They require fewer parts to replace and are less prone to wear and tear compared to larger machines. Additionally, their smaller engines and systems are more durable and easier to repair, reducing the need for frequent servicing.

Fuel Efficiency and Long-Term Savings

Mini road rollers are known for their fuel efficiency. Their smaller engines use less fuel than traditional models, making them a more eco-friendly and cost-effective choice for long-term use. Businesses can expect to see significant savings on fuel costs, especially on large projects where machinery is in use for extended hours.

High Productivity and Performance

Despite their smaller size, mini road rollers are capable of delivering excellent results in terms of both speed and quality.

Quick Compaction Time

Mini road rollers are designed to work efficiently without sacrificing performance. They have a fast compaction speed, allowing contractors to complete tasks in a shorter amount of time. This helps businesses meet tight deadlines while still delivering high-quality results.

Efficient Results with Minimal Labor

Mini road rollers are easy to operate, which translates into lower labor costs. Operators can achieve optimal compaction results without the need for extensive training. The intuitive controls and user-friendly design allow operators to focus on their work, leading to faster and more efficient compaction.

Better Quality of Work

Mini road rollers offer superior results when it comes to the quality of compaction. The precision and control they provide ensure that surfaces are uniformly compacted, leading to smoother roads, parking lots, and pathways. This is particularly important for projects where the final surface quality is critical.

Applications of Mini Road Rollers in Different Projects

Mini road rollers are highly versatile and can be used in a variety of construction and landscaping projects. Some common applications include:

Urban Roads and Pavements

Mini road rollers are frequently used in urban construction projects where space is at a premium. These compact machines can easily maneuver through city streets, compacting the soil or asphalt as needed. They are ideal for resurfacing small roads or creating new urban pavements in congested areas.

Parking Lots and Driveways

Mini road rollers are also a popular choice for working on residential driveways and commercial parking lots. Their small size allows them to navigate around curves and corners, ensuring smooth and even compaction. They are particularly useful for residential properties, where space for larger equipment is limited.

Pathways and Trails

Landscaping projects, such as creating garden pathways or outdoor trails, also benefit from the use of mini road rollers. These machines provide efficient compaction on softer materials like gravel or sand, ensuring that the surface is stable and durable.

How Mini Road Rollers Compare to Other Types of Rollers

While mini road rollers excel in certain areas, it’s important to understand how they compare to larger rollers.

Comparison with Standard Road Rollers

Compared to standard road rollers, mini road rollers are better suited for small-scale projects and tight spaces. They are more maneuverable and easier to transport, but they might not have the same compaction capacity as larger machines. For large-scale projects, traditional road rollers are still the preferred choice due to their higher compaction power.

Advantages Over Larger Rollers for Small Jobs

For smaller construction projects, mini road rollers are far superior to larger models. They are easier to operate, require less space to store, and are more affordable. Their lightweight design also means they can be used on more delicate surfaces without causing damage.

The Technology Behind Mini Road Rollers

Mini road rollers have come a long way in terms of technology. Today’s models come equipped with advanced features that improve performance and safety.

Engine Power and Types of Engines Used

Mini road rollers typically use smaller diesel or gasoline engines, which offer a balance between power and fuel efficiency. The power output varies depending on the model, but modern mini rollers are designed to provide sufficient compaction force without excessive fuel consumption.

Hydraulic Systems and Controls

Many mini road rollers now come with advanced hydraulic systems that enhance control and stability. These systems allow for smoother operation and more precise adjustments, making them easier to handle in a variety of conditions.

Latest Innovations in Mini Road Rollers

Recent innovations in mini road rollers include the integration of smart technologies like GPS tracking, automated compaction control, and eco-friendly engines that reduce emissions. These developments have made mini road rollers more efficient and environmentally friendly than ever before.

Safety Features in Mini Road Rollers

When it comes to construction machinery, safety is always a top priority. Mini road rollers, despite their smaller size, are equipped with several safety features that protect the operator and enhance the stability of the machine.

Operator Safety Protocols

Mini road rollers are designed with operator safety in mind. Most models come with a Rollover Protective Structure (ROPS) to safeguard the operator in the event of an accident. Additionally, these machines often feature a fully enclosed cabin or roll bar to protect the user from debris, vibrations, or falling objects.

To further ensure safety, many mini road rollers include advanced braking systems, such as hydrostatic brakes, which provide more control and reduce the risk of accidents. The ergonomically designed controls allow the operator to keep their hands and feet in a safe position while operating the machine, preventing potential injuries.

Stability and Control Mechanisms

Mini road rollers are designed with low centers of gravity to ensure maximum stability during operation. This is especially crucial when working on uneven or sloped terrain. Their small size also makes it easier to control them in tight spaces, reducing the likelihood of tipping or losing balance during compaction.

Additionally, many mini road rollers are equipped with vibration-damping systems that minimize the risk of operator fatigue and discomfort. These systems reduce the amount of vibration transferred to the operator, making the machine safer to use over extended periods.

Environmental Impact of Mini Road Rollers

As environmental concerns become more pressing, manufacturers of mini road rollers have started to focus on reducing their carbon footprint. These machines are designed to be more environmentally friendly than their larger counterparts, contributing to cleaner, greener construction practices.

Low Emissions and Eco-Friendly Features

Mini road rollers are built with engines that meet stringent environmental regulations. Many models are powered by low-emission diesel engines or even electric motors, which significantly reduce the amount of pollutants released into the air. These eco-friendly features help lower the overall carbon footprint of a construction project.

Additionally, mini road rollers are designed to consume less fuel, contributing to a decrease in fuel emissions over time. This makes them an excellent choice for contractors looking to reduce their environmental impact without compromising on performance.

Noise Reduction in Urban Areas

Another environmental benefit of mini road rollers is their relatively low noise levels. Construction projects in urban areas often face strict noise regulations, and mini road rollers help mitigate noise pollution. Their smaller engines and advanced muffling systems reduce the noise output, making them ideal for use in residential areas or busy city centers.

Green Technology in Mini Road Rollers

With sustainability being a growing priority, many mini road rollers are now being equipped with green technologies that not only improve performance but also reduce environmental impact.

The Use of Alternative Fuels

Some of the latest mini road rollers are powered by alternative fuels such as biofuels or compressed natural gas (CNG), which further reduces their environmental footprint. These fuels produce fewer greenhouse gas emissions and are often more affordable than traditional fuels, making them an attractive option for eco-conscious contractors.

Sustainable Manufacturing Practices

In addition to their eco-friendly fuel sources, many mini road rollers are now manufactured using sustainable practices. This includes using recyclable materials in the construction of the machine and minimizing waste during the production process. Some manufacturers also incorporate energy-efficient production techniques, reducing the carbon footprint of the manufacturing process.

Common Maintenance Tips for Mini Road Rollers

Maintaining a mini road roller is crucial for ensuring its longevity and optimal performance. Regular maintenance not only helps keep the machine running smoothly but also prevents costly repairs down the line. Here are some common maintenance tips to keep in mind:

Routine Checks and Inspections

Before operating a mini road roller, it’s essential to conduct routine checks to ensure everything is functioning correctly. This includes inspecting the engine, hydraulic systems, and safety features. Regular checks on the tires, drum, and other critical components will help identify any issues early and prevent potential breakdowns.

Tire and Drum Maintenance

The tires and drums are among the most important parts of a mini road roller, as they directly affect the quality of compaction. Regularly inspect the tires for signs of wear and tear, and ensure they are properly inflated for optimal performance. The drum should be kept clean and free from debris to maintain its compaction ability. Any damage to the drum, such as dents or cracks, should be repaired immediately to avoid compromising the machine’s efficiency.

Engine Care and Longevity

The engine of a mini road roller is essential to its performance, so proper care is crucial. Be sure to change the oil at regular intervals, check the air filters, and ensure that the cooling system is functioning well. Keeping the engine clean and free of debris will help prolong its lifespan and maintain the machine’s performance.

Importance of Regular Oil Changes

Like any machinery, regular oil changes are necessary to keep the engine running smoothly. Fresh oil helps reduce friction, prevent overheating, and protect internal components. Check the oil level regularly and replace it as recommended by the manufacturer to ensure optimal engine performance.

Conclusion

Mini road rollers offer a wide range of advantages, from cost-effectiveness and maneuverability to enhanced safety and environmental benefits. Whether you’re working on a small residential project or a larger construction job, mini road rollers provide the perfect balance of performance, precision, and efficiency. Their compact size and advanced technology make them an invaluable tool for contractors and businesses looking to streamline their operations while keeping costs low.

As the construction industry continues to evolve, mini road rollers are sure to remain a key part of many projects, especially as they become more eco-friendly and innovative. If you’re considering adding one to your equipment fleet, you can expect a durable, reliable, and versatile machine that can handle a variety of tasks with ease.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.