Power Trowel

When you are looking for a power trowel, we can assist you in selecting the most suitable concret finish power trowel for your business.

Home » Construction Machinery » Power Trowel

Description

Power trowel is a construction machine used to impart a smooth surface finish on freshly poured concrete slabs. This machine consists of one rotor which rotate parallel with the slab surface. Discs or multi-bladed attachments are spun against the still soft concrete surface by the rotors, thereby effectively smoothing out any blemishes or high spots.

When concrete slabs have been thrown, the surface of the concrete is uneven and rough. Most construction specifications require an even slab surface which requires the concrete to be smoothed before it sets and cures. A screed is used to smooth the surface on small slabs, sidewalks, and walkways. A screed is a flat wooden, steel, or aluminum beam that is drawn across the concrete surface to smooth out any high and rough spots. On larger slabs, this method is impractical, and the power trowel comes into its own as the preferred method of surface finishing.

| Model | PME-S60 |

|---|---|

| Engine | Honda GX160, Loncin G200F, Robin EY20, B&S 1062 |

| Engine type | Air-cooled, single cylinder, 4-stroke, petrol engine |

| Trowel diameter [mm] | 580 |

| Speed range [r/min] | 60-100 |

| Pitch range | 0-15° |

| N.W./G.W. [kg] | 56/66 |

| Package (L x W x H) [cm] | 67x67x75 |

| Model | PME-S80 |

|---|---|

| Engine | Air-cooled,single cylinder,4-stroke,petrol engine |

| Engine type | Honda GX160, Loncin G200F, Robin EY20, B&S 1062 |

| Trowel diameter [mm] | 760 |

| Speed range [r/min] | 60-100 |

| Pitch range | 0-15° |

| N.W./G.W. [kg] | 66/76 |

| Package (L x W x H) [cm] | 82x82x75 |

| Model | PME-S100 |

|---|---|

| Engine | Honda GX160, Loncin G200F, Robin EY20, B&S 1062 |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine |

| Trowel diameter [mm] | 910 |

| Speed range [r/min] | 60-100 |

| Pitch range | 0-15° |

| N.W./G.W. [kg] | 78/88 |

| Package (L x W x H) [cm] | 102X102X75 |

| Model | PME-S120 |

|---|---|

| Engine | Honda GX270, Loncin G270, Robin EY28 |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine/diesel engine |

| Trowel diameter [mm] | 1170 |

| Speed range [r/min] | 60-100 |

| Pitch range | 0-15° |

| N.W./G.W. [kg] | 96/110 |

| Package (L x W x H) [cm] | 125x125x85 |

Parameters comparison

| Model | PME-S60 | PME-S80 | PME-S100 | PME-S120 |

|---|---|---|---|---|

| Trowel diameter [mm] | 580 | 760 | 910 | 1170 |

| Speed range [r/min] | 60-100 | 60-100 | 60-100 | 60-100 |

| Pitch range | 0-15° | 0-15° | 0-15° | 0-15° |

| N.W./G.W. [kg] | 56/66 | 66/76 | 78/88 | 96/110 |

| Package (L x W x H) [cm] | 67x67x75 | 82x82x75 | 102X102X75 | 125x125x85 |

When concrete slabs have been thrown, the surface of the concrete is uneven and rough. Most construction specifications require an even slab surface which requires the concrete to be smoothed before it sets and cures. Power trowel comes into its own as the preferred method of surface finishing. It is used to smooth the surface on small slabs, sidewalks, and walkways.

| Model | PME-RS80 | PME-RS100 |

|---|---|---|

| Engine | Honda GX390,13HP | Honda GX690 |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine | Air-cooled,two cylinder,4-stroke,petrol engine |

| Trowel diameter [mm] | 1600 | 1920 |

| Speed range [r/min] | 60-100 | 60-100 |

| Pitch range | 0-15° | 0-15° |

| N.W./G.W. [kg] | 285/372 | 358/468 |

| Package (L x W x H) [cm] | 182×103×113 | 222×125×115 |

Application

Power Trowel Advantages

High-Speed Operation

Equipped with a powerful motor that enables high rotational speeds, ensuring efficient and smooth finishing of concrete surfaces.

Adjustable Blade Pitch

Features adjustable blade pitch control, allowing for precise finishing and achieving the desired surface texture and smoothness.

Ergonomic Design

Designed with operator comfort in mind, incorporating features like vibration-dampening handles and easy maneuverability for extended periods of use.

Versatile Applications

Suitable for a wide range of applications, including finishing floors in residential, commercial, and industrial settings.

How a Power Trowel Works

Basic Mechanism

A power trowel works by rotating its blades at high speed over the concrete surface. This action smooths and compacts the concrete, creating a dense and level finish.

Different Functions of Blades

Different blades are used for different stages of the finishing process. Float blades are used initially to level the surface, while finish blades give the concrete its final, smooth appearance.

Types of Power Trowels

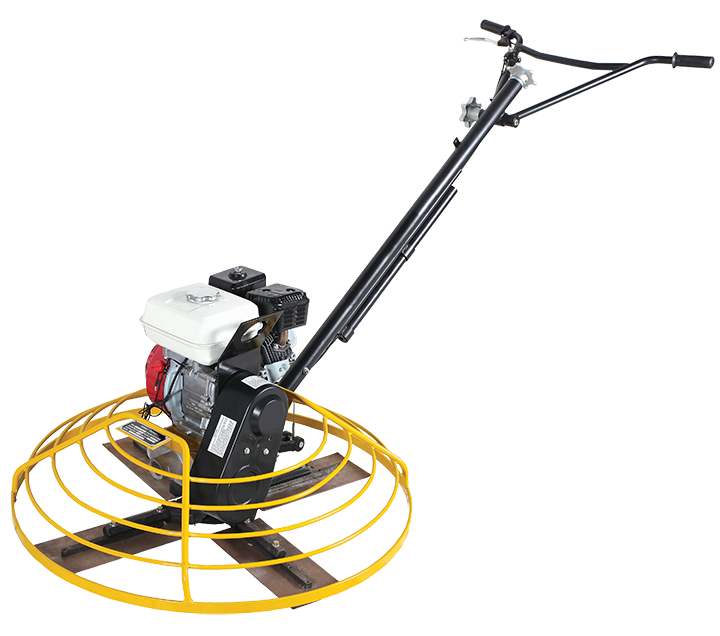

Walk-Behind Power Trowels

Walk-behind power trowels are ideal for smaller projects or areas where maneuverability is crucial. They require the operator to walk behind the machine, guiding it over the surface.

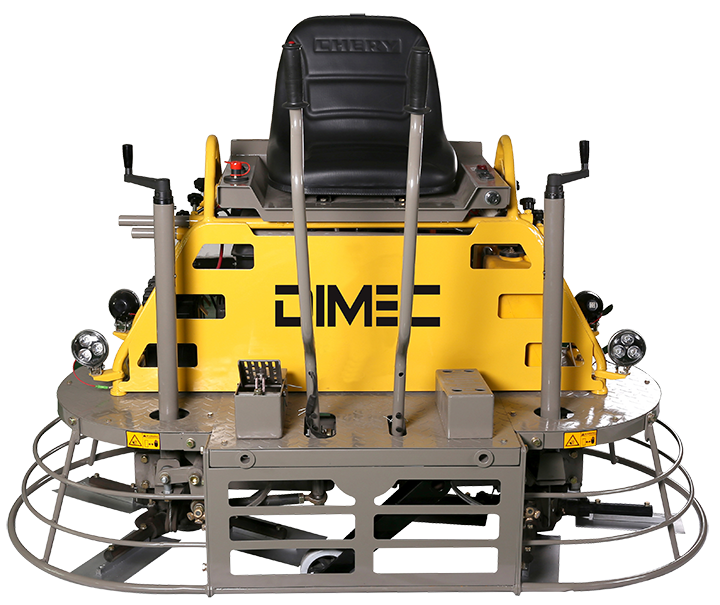

Ride-On Power Trowels

For larger projects, ride-on power trowels are the go-to option. These machines allow the operator to sit or stand on the trowel, covering more ground efficiently and with less physical exertion.

Key Components of a Power Trowel

Blades

The blades are the heart of the power trowel, responsible for smoothing and finishing the concrete. They come in different types for different stages of the finishing process.

Engine

The engine powers the trowel, and its efficiency directly impacts the performance of the machine. Common engines are either gasoline or electric.

Handle

The handle allows the operator to control the trowel. In walk-behind models, it’s crucial for maneuvering, while in ride-on models, it houses the controls.

Choosing the Right Power Trowel

Factors to Consider

When selecting a power trowel, consider the size of your project, the type of concrete finish desired, and your budget. Other factors include the power source (gasoline vs. electric) and the ease of maintenance.

Popular Brands

Brands like Wacker Neuson, PME, Allen Engineering, and Multiquip are renowned for their reliable and high-performance power trowels. Choosing a reputable brand ensures better support and spare parts availability.

Using a Power Trowel

Preparation Before Use

Before using a power trowel, ensure that the concrete is at the right stage of curing. It should be firm enough to support the machine but still pliable for finishing.

Operating Techniques

Operate the power trowel by guiding it smoothly over the concrete surface. Start with float blades to level the surface, then switch to finish blades for the final pass. Maintain a steady pace to avoid uneven finishes.

Power Trowels vs. Hand Tools

Comparative Analysis

While hand tools are suitable for small, intricate jobs, power trowels are unbeatable for large surfaces. They provide a superior finish and save a significant amount of time and effort.

When to Use Each

Use hand tools for touch-ups and small areas where precision is key. For large slabs and floors, a power trowel is the best choice for a smooth and even finish.

The concrete should be firm enough to support the machine but still pliable for finishing.

Regular maintenance should be performed after every use, with more thorough checks monthly or as recommended by the manufacturer.

Yes, walk-behind power trowels are ideal for smaller projects and areas requiring more maneuverability.

Common issues include engine troubles, blade wear, and handle malfunctions.

While they can be a significant investment, the efficiency and quality of finish they provide often justify the cost.

Maintenance

Power Trowel Periodic Maintenance Schedule

| | Daily Before Starting | After First 5 Hrs. | After First 50 Hrs. | Every Week or 25 Hrs. | Every month or 100 Hrs. | Every 3 months or 300 Hrs. |

|---|---|---|---|---|---|---|

| Check fule level and fittings for cracks or leaks | √ | |||||

| Check oil level of machine | √ | |||||

| Check and tighten engine cylinder screws | √ | √ | ||||

| Check and tighten external hardware | √ | √ | ||||

| Clean engine cooling fins | √ | |||||

| Clean recoil starter | √ | |||||

| Change gearbox oil | √ | √ | ||||

| Clean engine muffler and exhaust port | √ |

Note: If engine performance is poor,please check,clean and replace air filter elements as needed.

Engine periodic maintenance schedule

| Each use | First month or 20 hours | Every 3 months or 50 hours | Every 6 months or 100 hours | Every year or 300 hours | ||

|---|---|---|---|---|---|---|

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √☆ | |||||

| Sediment Cup | √ | |||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Spark arrester(optional parts) | Clean | √ | ||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel tank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

☆ Replace the paper element type only.

(1)Service more frequently when used in dusty areas.

(2)These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures.

Performed at every indicated month or operating hour interval, whichever comes first.