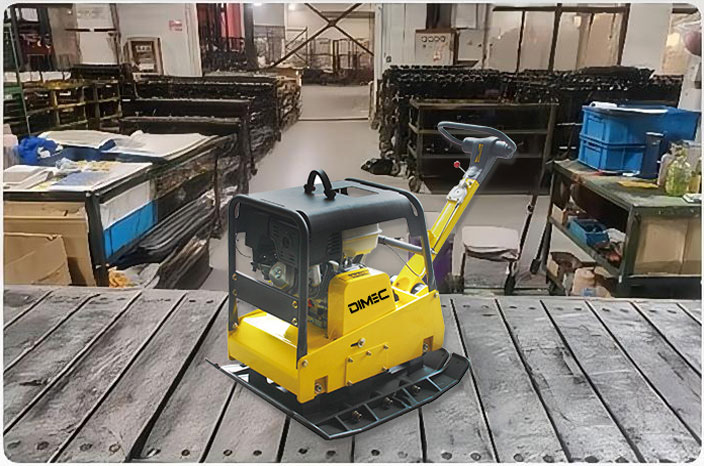

Vibrator Compactor PME-CY300

When you are looking for a vibrator compactor, we can assist you in selecting the most suitable plate compactor for your business.

Vibrator Compactor PME-CY300

The PME-CY300 Vibrator Compactor is a powerhouse in soil and material compaction, designed for large-scale projects requiring deep and efficient compaction. Powered by options from Honda, Robin, Loncin, or Diesel engines, this model delivers exceptional performance across a range of demanding applications.

High-Impact Compaction Capability

The PME-CY300 boasts a large plate size of 84 cm x 68 cm, producing a centrifugal force of 38 KN, and achieving a maximum compaction depth of up to 90 cm. Operating at a frequency of 4,800 VPM, this compactor is ideal for high-demand tasks, from roadwork to landscaping and heavy-duty construction projects. Its impressive efficiency of 850 square meters per hour, combined with a travel speed of 25 meters per minute, allows operators to cover extensive areas quickly and with professional precision.

Versatile Design for Various Applications

Built to handle challenging surfaces, the PME-CY300 performs well on both flat and inclined terrain, with a maximum inclination angle of 20°. Its robust plate size and powerful engine options make it suitable for compacting different materials, from granular soils to mixed aggregates, providing reliable results in diverse conditions.

Built for Professional Durability

Weighing 285 kg (net) and 270 kg (gross), the PME-CY300 is designed for stability and long-lasting performance. The package dimensions of 90 cm x 67 cm x 125 cm allow for efficient transport and storage, while its durable construction ensures it can handle continuous heavy use. With a 1-year warranty, the PME-CY300 is a solid investment for contractors and professionals who require powerful, efficient, and durable compaction equipment on the job.

Applications

- Retaining Walls

- Footings and Foundation Projects

- Landscapes and hardscapes

- Patchwork on Asphalt

- Pipeline Applications

- Road Repair and Trenchwork

- Cohesive Soils and Granular Soils

- Sticky soils – such as clay or clayey silt

- Gravel, sand, silt, clay, or mixed soils

- Base, Subbase, Subgrade, Subsoil

- Backfill Pools, Parks, Cemeteries, and Golf Courses

Key Specifications

| Model | Vibrator Compactor PME-CY300 |

|---|---|

| Engine | Honda / Robin / Loncin / Diesel engine |

| Engine type | Air-cooled, single cylinder, 4-stroke, petrol engine / diesel engine |

| Frequency [VPM] | 4800 |

| Centrifugal force [KN] | 38 |

| Plate size (LxW) [cm] | 84x68 |

| Max.compaction depth[cm] | 90 |

| Travel speed [m/min] | 25 |

| Max.inclination angle | 20° |

| N.W./G.W. [kg] | 270/285 |

| Package (LxWxH) [cm] | 90x67x125 |

ADVANTAGE

Low vibration comfortable operation

Heavy-duty shock absorber system that effectively improves operating comfort by reducing shock to arms.

12.9 Grade bolts

High-strength bolts with exceptional durability, providing reliable fastening even under intense pressure and demanding conditions.

High strength engine frame

The material of thickened steel pipe has strong supporting force and stable gravity bearing capacity.

Strong power brand engine

Well-know brand engines Honda, Robin, Loncin low noise, low maintenance, low consumption.

Low oil sensor

Advanced low oil sensor technology ensures automatic engine protection by preventing operation when oil levels are insufficient, extending engine life.

Professional spraying process

Utilizes advanced spraying techniques to deliver a smooth, even coating that resists wear, corrosion, and fading, ensuring long-lasting protection and aesthetic appeal.

QUESTIONS & ANSWERS

Granular soils, such as sand and gravel, are the easiest to compact due to their loose particles and low moisture retention.

Yes, but ensure it’s not overly saturated. Damp soil is ideal, as it compacts well without becoming too dense or muddy.

It’s best to check settings at the start of each use and adjust based on the soil type and material requirements.

Yes, ear protection is important as compactors can be loud, potentially causing hearing damage with prolonged exposure.

Signs of over-compaction include cracking, excessive hardness, and reduced soil permeability. Adjust the vibration settings if you notice these signs.

Other Similar Products

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Hydraulic Reversible Plate Compactor

The Hydraulic Reversible Plate Compactor is a vital tool for construction and landscaping, designed for effective soil compaction in various environments. Its advanced hydraulic system allows for seamless forward and reverse operation, making it ideal for compacting asphalt and granular soils. With high-frequency vibrations, this compactor efficiently densifies materials, ensuring a solid foundation for roads, patios, and driveways.

This machine excels in tight spaces where traditional compactors may struggle, thanks to its lightweight design and powerful compaction force. Adjustable speed settings provide tailored performance to meet specific project needs, enhancing productivity.

How to Use a Vibrator Compactor Effectively

Introduction

What is a Vibrator Compactor?

A vibrator compactor, commonly used in construction and landscaping, is a powerful tool designed to compact soil, gravel, and asphalt surfaces. This compactor creates vibrations that pack materials tightly, reducing air pockets and creating a solid foundation. Effective compaction leads to stable, long-lasting surfaces, making vibrator compactors essential for projects like laying foundations, paving driveways, and installing roadbeds.

Importance of Effective Compaction

Proper compaction is vital for construction integrity, preventing issues such as settling, cracking, and erosion. Whether for large-scale construction or smaller DIY projects, understanding how to use a vibrator compactor effectively ensures structural durability, safety, and longevity.

Understanding Vibrator Compactors

Types of Vibrator Compactors

Vibrator compactors come in various models, each suited for different applications. The main types include:

- Plate Compactors – Used primarily for flat surfaces like driveways and sidewalks.

- Jumping Jack Compactors – Ideal for confined areas and trench work.

- Roller Compactors – Best for large-scale projects like road construction.

Key Components and Functions

Each type of vibrator compactor has unique components, but the essential parts include:

- Base Plate – Applies pressure to the ground.

- Vibration Mechanism – Creates oscillations to achieve compaction.

- Engine – Powers the compactor, usually a gasoline or diesel motor.

Preparation for Using a Vibrator Compactor

Checking the Area

Before beginning, ensure the compaction area is free of debris and obstructions. Uneven ground can lead to inconsistent compaction, so use a leveling tool to check for any dips or raised spots.

Inspecting the Compactor

Perform a quick inspection of the compactor. Check the fuel, oil levels, and the condition of the vibration mechanism to prevent malfunctions during operation.

Ensuring Proper Safety Gear

Safety gear is essential for handling heavy machinery. Basic protective equipment includes:

- Hearing Protection – To protect against prolonged exposure to loud noise.

- Gloves – For grip and to absorb some of the vibrations.

- Steel-toed Boots – To prevent injuries if the compactor accidentally slips.

Safety Precautions

Safety Gear Essentials

Wearing the correct safety gear minimizes the risk of injury. Make sure to secure loose clothing and avoid wearing jewelry, as vibrations can cause objects to snag.

Operating in Confined Spaces

Operating compactors in confined spaces, like trenches, requires careful positioning and handling to avoid getting trapped or injured by the equipment.

Handling Compactor Vibrations Safely

Prolonged exposure to vibration can lead to Hand-Arm Vibration Syndrome (HAVS). Take frequent breaks, and avoid holding the compactor too tightly, which can amplify vibrations.

How to Start and Operate a Vibrator Compactor

Starting Procedures

To start a vibrator compactor:

- Prime the Engine by pumping the fuel line if necessary.

- Engage the Choke, especially if starting in cold conditions.

- Pull the Start Cord or engage the electric start, depending on the model.

Adjusting Compactor Settings

Adjust the compactor’s frequency and amplitude according to the material. Higher frequencies work better for sand, while lower frequencies are suitable for dense clay soils.

Operating Tips for Consistent Compaction

For a uniform compaction, move the compactor in a grid pattern. Avoid stopping mid-pass as this can create uneven compaction.

Choosing the Right Settings for Optimal Results

Understanding Frequency and Amplitude

Frequency and amplitude adjustments influence how well the compactor compresses the material. Select higher frequency for loose soils and lower amplitude for dense materials.

Matching Settings to Soil Type

Different soil types require different approaches:

- Sand – High frequency, moderate amplitude.

- Clay – Low frequency, high amplitude.

- Gravel – Medium settings for both frequency and amplitude.

Step-by-Step Guide to Compacting Different Materials

Compacting Soil

Use a plate compactor for soil surfaces. Start on one end and work in a linear direction with overlapping passes.

Compacting Gravel

Gravel compaction needs a sturdy roller or plate compactor. Compact in several layers to achieve maximum density.

Compacting Asphalt

Asphalt requires uniform, steady compaction. Work quickly, as asphalt cools fast, making it harder to compact.

Techniques for Better Compaction

Proper Overlapping Technique

Overlap each pass by at least one-third of the plate’s width. This ensures no area is missed, leading to a consistent compaction.

Maintaining a Steady Pace

Operating at a steady speed reduces the risk of under or over-compaction, providing a smoother surface.

Avoiding Over-Compaction

Excessive compaction can make the material too dense, leading to cracks. Stop after a few passes to inspect the surface.

Common Challenges and How to Overcome Them

Tackling Wet or Muddy Conditions

Avoid compaction when the ground is too wet. Muddy areas won’t compact effectively and may cause the compactor to slip.

Compacting on Slopes

When working on a slope, start at the bottom and work upwards in a gradual, side-to-side motion.

Techniques for Effective Compaction

For the best results, compact the area in overlapping passes. This technique ensures that no areas are left uncompressed, resulting in a smooth, uniform surface. Adjust the vibration settings based on the material you’re compacting; finer materials often require a lower vibration setting, while coarser materials benefit from higher vibration.

Managing Different Soil Types

Different soils require different compaction methods. Moisture levels are critical, as overly wet or dry soils can be difficult to compact. Cohesive soils, like clay, may need additional passes and moisture for effective compaction, while granular soils can generally be compacted quickly.

Compacting in Layers

Compacting in layers of approximately 4 to 6 inches is recommended for achieving strong results. If the layers are too thick, the compactor may not be able to reach the lower layers, resulting in uneven compaction. By working in thin layers, you can ensure that each level is compacted properly.

Controlling Vibration Frequency

The vibration frequency should be adjusted according to the material’s characteristics. A frequency that’s too high can cause over-compaction, while a low frequency may not achieve the desired density. Experiment with different settings to find the best frequency for your material.

Using Water for Better Compaction

Adding moisture to the soil can enhance compaction, especially for cohesive soils. However, it’s essential to avoid over-wetting, which can lead to a mud-like consistency that’s difficult to work with. Aim for a damp, crumbly texture for the best results.

Checking Compaction Quality

To verify compaction quality, observe the material for any signs of settling or displacement. You can also conduct a “proof roll” test, where a heavy vehicle is driven over the compacted area. If the surface remains level and stable, the compaction is likely adequate.

Common Mistakes to Avoid

Avoid over-compacting or under-compacting, as both can compromise the foundation’s stability. Be mindful of the soil type, moisture level, and machine settings to ensure effective compaction without damaging the soil structure.

Conclusion

Effective use of a vibrator compactor is essential for construction stability and longevity. By following this guide, understanding material settings, and applying safe techniques, you can achieve professional-quality compaction on various surfaces.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.