Vibratory Roller Compactor PME-R1000

When you are looking for a vibratory roller compactor, we can assist you in selecting the most suitable compactor roller for your business.

Vibratory Roller Compactor PME-R1000

The PME-R1000 Vibratory Roller Compactor is a powerhouse of efficiency and precision, designed to handle heavy-duty compaction tasks with ease. Its dual rollers, measuring 530 mm in diameter and 700 mm in width, offer robust performance, making this machine the ideal choice for large-scale road construction, foundation preparation, and complex infrastructure projects.

Powerful Performance

The PME-R1000 is powered by either a Honda GX390 or ChangFa CF186FAE engine, delivering exceptional reliability and consistent power for demanding compaction jobs. Its 4-stroke engine ensures smooth, efficient operation over extended periods. With a centrifugal force of 30 KN and a vibration frequency of 75 Hz, the roller provides deep and uniform compaction for asphalt, gravel, and soil. The electromagnetic vibration control system ensures precise and targeted performance with a nominal amplitude of 0.5 mm, catering to a variety of materials and surfaces.

Versatile Application

Designed for versatility, the PME-R1000 excels in a wide range of applications, including road construction, soil stabilization, and foundation preparation. Its hydraulic drive system, coupled with stepless speed control, allows for smooth transitions and adaptability to varying job site conditions. The hydraulic steering system offers a steering radius of 2000 mm, providing superior maneuverability even in constrained spaces. With a gradeability of 30° and a travel speed of up to 8 km/h, the PME-R1000 performs efficiently on slopes and uneven terrain, ensuring precision and speed in all environments.

Built to Last

Engineered with durability in mind, the PME-R1000 is constructed from high-quality materials to withstand the rigors of demanding construction sites. Its advanced hydraulic systems ensure smooth operation and minimize maintenance downtime. The machine’s robust design, combined with precise vibration control, ensures long-lasting performance and reliability. Whether used for compacting subgrades, stabilizing soil, or preparing large foundations, the PME-R1000 is built to deliver consistent and outstanding results.

Applications

- Road Construction and Maintenance

- Asphalt, Gravel, and Soil Compaction

- Foundation and Subgrade Preparation

- Soil Stabilization Projects

- Large-Scale Infrastructure Development

- Compaction on Slopes and Uneven Terrain (Gradeability: 30°)

- Tight and Open Workspaces

- Pathways, Driveways, and Landscaping

With its powerful engine, advanced hydraulic systems, and precise vibration control, the PME-R1000 Vibratory Roller Compactor is a must-have for contractors and professionals seeking superior compaction results. Its robust features, combined with user-friendly operation, make it an essential tool for tackling even the most challenging construction tasks.

Key Specifications

| Model | Vibratory Roller Compactor PME-R1000 |

|---|---|

| Engine | Honda GX390/ ChangFa CF186FAE |

| Roller size [diameter x width] | 2xφ530x700 mm |

| Drive type | Hydraulic drive, Stepless speed change |

| Vibration type | Electromagnetic control |

| Steering mode | Hydraulic control |

| Steering radius | 2000 mm |

| Nominal amplitude | 0.5 mm |

| Vibration frequency | 75 Hz |

| Centrifugal force | 30 KN |

| Gradeability | 30° |

| Travel speed | 0-8 km/h |

| N.W./G.W. | 1000/1020 kg |

| Package size | 220x95x165 cm |

ADVANTAGE

Exquisite Workmanship

The hood of the road roller showcases excellent craftsmanship. The bright yellow paint is flawlessly applied, providing a smooth and vibrant finish.

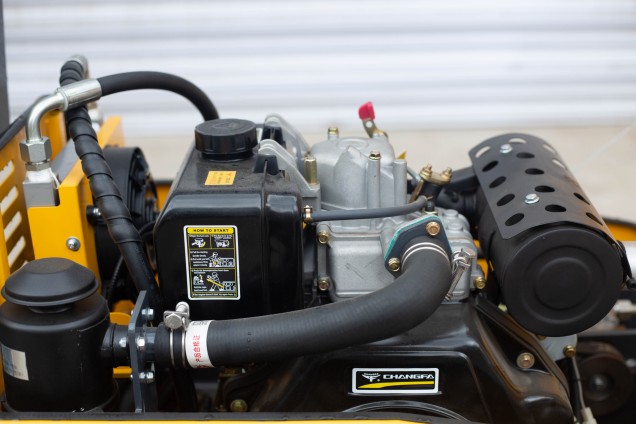

Efficient Engine Compartment Organization

The engine compartment is organized with components such as hoses, filters, and the engine block properly placed.This organized layout facilitates maintenance and ensures the smooth operation of the road roller's engine.

Large Compaction Drum

The roller features a large compaction drum at the front. This drum is responsible for compacting soil, asphalt, and other construction materials. The large size of the drum ensures a smooth and even compaction surface.

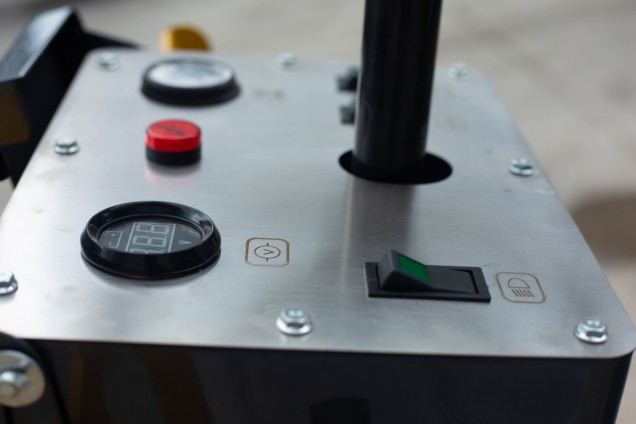

Intuitive Control Panel Layout

The control panel features a well - arranged layout with clearly marked buttons and gauges. This design allows for easy access and operation, reducing the likelihood of errors and improving the efficiency of the road roller's functions.

Comfortable Seat

The roller is equipped with a cushioned seat, providing comfort for the operator during extended use. It is flanked by handlebars, providing a secure and comfortable operating position for the operator, which enhances the overall usability of the road roller.

Drum with Scraper

The roller is equipped with a drum that has a built - in scraper. The scraper helps to remove any material that may stick to the drum during the compaction process, ensuring that the drum remains clean and effective. This feature is crucial for maintaining the quality of the compaction work.

QUESTIONS & ANSWERS

Vibratory rollers compact soil and other materials to improve density and stability, making them suitable for construction projects.

While effective on many soil types, they may struggle with overly wet or clay-heavy soils.

Single drum rollers are best for smaller projects, while double drum rollers provide uniform compaction for larger areas.

Factors include size, power output, brand, and additional features like advanced controls or eco-friendly systems.

Newer models are designed with eco-friendly features like lower emissions and fuel efficiency.

Regular servicing every 200–500 hours of operation is recommended to maintain performance.

Operators should wear PPE, perform pre-use inspections, and follow all safety guidelines.

Other Similar Products

20+ Years of Experience

Construction Machine Manufacturer

Professional manufacturer of small construction machinery, main products include plate compactor, tamping rammer, road roller,floor saw, concrete vibrator, generator etc.

Vibratory Roller Compactor

A vibratory roller compactor is a heavy-duty machine designed for soil and asphalt compaction. It uses a combination of static weight and vibration to achieve maximum density in various materials. This makes it a go-to choice for contractors who need efficient, reliable compaction.

How Does a Vibratory Roller Compactor Work?

Introduction

The vibratory roller compactor is a cornerstone of modern construction, ensuring surfaces are stable and durable. Whether it’s for laying down roads, preparing a foundation, or maintaining airport runways, these machines offer unparalleled efficiency. But how exactly does a vibratory roller compactor work? Let’s delve into the mechanisms, applications, and benefits of this indispensable equipment.

Vibratory roller compactors harness mechanical vibrations to achieve optimal compaction, addressing challenges like soil instability and uneven surfaces. Their role in infrastructure projects cannot be overstated, as they contribute directly to the longevity and performance of various structures.

What is a Vibratory Roller Compactor?

Definition and Purpose

A vibratory roller compactor is a heavy-duty construction machine designed to compact soil, asphalt, and other materials through a combination of static weight and vibratory force. Its primary purpose is to remove air voids, increase density, and improve load-bearing capacity, ensuring the foundation is stable and capable of supporting the intended structure.

Types of Roller Compactors

There are several types of roller compactors, each suited for specific applications:

Single Drum Rollers: Ideal for large open areas like roads and highways.

Double Drum Rollers: Equipped with two drums for maximum surface coverage.

Pneumatic Rollers: Utilize rubber tires for flexible compaction.

Static Rollers: Rely solely on their weight for compaction, without vibrations.

Each type has unique advantages, allowing construction professionals to choose the right equipment for their project needs.

Core Components of a Vibratory Roller

Drum Assembly and Its Variants

The drum is the heart of a vibratory roller. It comes in different sizes and designs, including smooth drums for general applications and padfoot drums for cohesive soils. The drum’s weight and vibration are critical for achieving effective compaction.

Vibration Mechanism

The vibration mechanism involves an eccentric rotating mass inside the drum, which generates high-frequency oscillations. These vibrations penetrate the soil, rearranging particles to eliminate voids and improve density.

Engine and Power Transmission Systems

Modern vibratory rollers are powered by robust engines that provide the necessary force. The power transmission system ensures that energy from the engine is efficiently delivered to the drum and vibration mechanism, optimizing performance.

Principle of Operation

How Vibration Improves Soil Compaction

The principle of operation lies in the vibratory force, which helps overcome soil’s internal resistance. The oscillations cause soil particles to move closer together, filling gaps and increasing density. This results in a compact and stable surface.

Role of Frequency and Amplitude

Frequency: Refers to the number of vibrations per second. Higher frequencies are suited for granular materials.

Amplitude: Denotes the depth of vibration. Higher amplitudes are effective for cohesive soils.

The operator can adjust these parameters to suit the material and achieve desired compaction results.

How It Works on Different Soil Types

Compaction Techniques for Cohesive Soils

Cohesive soils, such as clay, require higher amplitude vibrations. Padfoot drums are often used to break down the material’s stiffness, allowing for deeper compaction.

Methods for Granular Soils

Granular soils like sand and gravel compact well with high-frequency vibrations. Smooth drums are preferred for these applications, as they provide uniform results.

Advantages of Using a Vibratory Roller

Enhanced Soil Stability

By eliminating air pockets and achieving uniform density, vibratory rollers ensure that the foundation can support heavy loads without shifting or settling.

Time and Cost Efficiency

These machines work faster and more effectively than traditional compaction methods, reducing labor costs and project timelines.

Applications in Construction

Roads and Highways

Vibratory rollers are essential for creating durable road surfaces that can withstand heavy traffic. They ensure smooth and even asphalt layers, preventing cracks and potholes.

Foundations and Building Pads

In building construction, a stable foundation is crucial. Vibratory rollers compact soil layers to provide the necessary support for structures.

Airport Runways

Runways require a high level of compaction to handle the immense weight and speed of aircraft. Vibratory rollers achieve the density needed for these demanding applications.

Safety Features and Operational Controls

Key Safety Mechanisms

Modern vibratory rollers include features like operator cabins with safety harnesses, emergency stop systems, and automatic shut-off in case of malfunctions.

How to Operate a Vibratory Roller Safely

Operators should always follow manufacturer guidelines, conduct pre-operation inspections, and use appropriate personal protective equipment (PPE).

Maintenance and Upkeep

Regular Maintenance Practices

Routine inspections, lubrication of moving parts, and timely replacement of worn components ensure that the machine operates efficiently.

Troubleshooting Common Issues

Common problems include excessive vibration, drum imbalance, and engine overheating. Addressing these promptly minimizes downtime and repair costs.

Environmental Considerations

Impact on Surrounding Ecosystems

Vibratory rollers can affect nearby vegetation and soil structure. Proper planning and eco-friendly practices mitigate these impacts.

Innovations for Eco-Friendly Operations

Manufacturers are introducing electric and hybrid rollers to reduce emissions, as well as noise-dampening technologies for urban environments.

Factors to Consider When Choosing a Vibratory Roller

Size and Weight

The roller’s size and weight determine its effectiveness for specific applications. Larger rollers are ideal for expansive projects, while smaller models suit confined spaces.

Power Output and Drum Type

Selecting the right power output and drum type ensures optimal performance and compatibility with project requirements.

Challenges and Limitations

Operating Challenges in Wet Conditions

Excess moisture can hinder compaction efforts. Operators must adapt techniques or wait for suitable conditions.

Managing Vibration-Induced Wear

Prolonged use of vibratory rollers can cause wear on components. Regular maintenance is essential to prevent equipment failure.

Conclusion

Vibratory roller compactors are vital tools in construction, ensuring that foundations and surfaces are compact, stable, and durable. By understanding their mechanisms, applications, and maintenance needs, professionals can maximize the efficiency and lifespan of these machines. As technology advances, the future promises even more innovative and sustainable solutions for soil compaction.

About Us

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) As a first-class specialty enterprise we serve global clients. PME specialize on production of plate compactor, tamping rammer, floor saw, concrete vibrator for global construction industry. We also produce engine, generator, and water pump. PME’s strengths are rooted from our strong team and rich resources.

We have complete production and assembly lines for different machines. There is a team of chief engineers, senior technicians and QC inspectors, equipped with a variety of finishing, spare parts inspection and product testing equipment, to safeguard production and innovation. Thus, we can control every step of production, from finish machining of spare parts, steel plate cutting and welding, spraying paint, all the way to product assembly. This results in effective product quality control.

With more than 20 years of exporting experience, PME has been exporting to over 68 countries and regions including North America, South America, Europe, Southeast Asia, Middle East, Africa. We also form strategic corporations with many multinational companies.

Factory Show

Let our expertise in custom Forward Plate Compactor take your projects to the next level.

Why Choose Us

Professional construction machinery manufacturer with OEM service

We are a leading manufacturer in the construction machinery industry, offering top-notch Original Equipment Manufacturer (OEM) services. Our commitment to innovation and precision engineering ensures that our machinery meets the specific needs of our clients, providing customized solutions that enhance efficiency and performance on the job site.

20 years production and exportation experience

With two decades of experience in production and exportation, we have built a strong reputation for delivering reliable and high-quality construction equipment worldwide. Our extensive knowledge and expertise in the industry enable us to understand the unique challenges of different markets, ensuring our products are tailored to meet global standards.

20+ types of construction site equipment are available for selection

We offer a diverse range of over 20 types of construction site equipment, catering to various industry needs. From heavy-duty machinery to specialized tools, our product lineup is designed to support every phase of construction, providing our clients with the flexibility to choose the right equipment for their projects.

10+ years QC monitor products quality

Our rigorous quality control processes have been refined over more than 10 years, ensuring that every piece of equipment we produce meets the highest standards. Our dedicated QC team meticulously monitors every stage of production, guaranteeing that our products deliver consistent performance and durability in the field.

8+ years experienced skilled workers

Our team comprises highly skilled workers with over 8 years of experience in the construction machinery industry. Their expertise and dedication are reflected in the precision and craftsmanship of our products, ensuring that every detail is executed to perfection.

8 workshops, 12 production lines

With 8 state-of-the-art workshops and 12 production lines, our manufacturing capabilities are designed to meet large-scale demands efficiently. Our advanced facilities allow us to maintain a streamlined production process, ensuring timely delivery of high-quality machinery to our clients around the world.

Unlock Superior Construction Efficiency with Our Expertly Engineered Machinery

Discover a world of advanced construction equipment tailored to meet the demands of modern job sites. With 20 years of industry experience and a commitment to quality, our machinery is designed to boost productivity and ensure reliability in every project. Explore our diverse range and experience the difference of precision-engineered solutions.